10

Tongue and Ramp Assembly Instructions

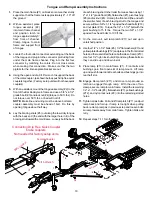

1.

Place the main frame (#1) on blocks or some other sturdy

support so that the frame rests approximately 8" - 10" off

the ground.

2.

With an assistant, place

tongue assembly (#2)

into main frame channel

and position latch on

tongue approximately 3”

from front of channel.

Clamp tongue to main

frame and support front

of tongue.

3.

Locate the four bullet connectors extending out the back

of the tongue and plug into the connector protruding from

under the main frame channel. Plug into the flat four

connector by matching the colors. Do not cross colors

when making this connection. Make sure that the two

pigtails for the license plate bracket are out.

4.

Using the open end of a 9/16” wrench to support the back

of the male coupler, (as shown below) push drip free quick

couplers together. (Factory setup units will not havequick

couplers)

5.

With an assistant, mount the tongue assembly (#2) to the

front of the Kar Kaddy main frame and use a 5/8" x 4-1/2"

grade 5 bolt (#3) and lock nut (#4)(torque to 50 ft. lbs). Do

not torque over 50 ft. lbs. or bed will not tilt.

NOTE: Brake line and wiring must be above bolt also

coupler assembly must be ahead of bolt. Do this by

opening tongue about half way.

6.

Lay the bracing struts (#5) out along the tow dolly tongue

with the back end (the end with the larger hole in it) of the

bracing strut toward the main frame. Loosely bolt the back

of each bracing strut to the trailer frame as shown using 1/

2" x 1-1/2" grade 5 bolt (#6), flatwasher (#7), pivot bushing

(#8) and locknut (#9). Hold up the front end (the end with

the smaller hole) of each bracing strut to the tongue and

secure with two 5/8" x 1-1/4" epoxied hex head bolts (#10)

and nut plate (#14). Torque the 1/2" x 1-1/2" bolt with the

pivot bushing to 75 ft. lbs. Torque the two 5/8" x 1-1/4"

epoxied hex head bolts to 100 ft. lbs.

7.

On the main unit, pull ramp latch (#11) out and up in

unlatched position.

8.

Use four 1/2” x 1-1/2” bolts (#6), 1/2” flat washers (#7) and

yellow plated bushings (#12) and place in the front slotted

hole and the rear slotted hole on both sides of ramp (#13).

Use four 1/2” nylon lock nuts (#9) and snug these bolts so

they can slide up and down in slot.

9.

Place ramp (#13) in main frame (#1). Front bolts and

bushings go in front open slot of ramp mount. Lift ramp

up and push forward until rear bolts and bushings go into

rear half slot.

10. Engage Ramp latch (#11) and move ramp around so

latch can engage through ramp. With the use of two

clamps, secure ramp to main frame. Install the remaining

1/2” x 1-1/2” bolts (#6), flatwashers (#7), yellow bushings

(#12), and nylon lock nuts (#9) into the remaining slotted

holes.

11. Tighten all six bolts. Pull and lift ramp latch (#11) and pull

ramp back and fold up. If ramp is too tight when pulling

back, reclamp ramp as in previous step and loosen bolts

so ramp lowers away from main frame. Tighten bolts and

retry.

12. Repeat steps 7-11 for other side.

Connector

1

2

3

4

5

5

6

7

8

9

9

6

7

8

10

10

6

6

6

7

7

7

9

11

12

12

13

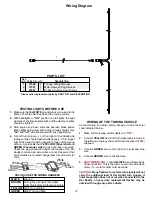

Female Coupler

Connecting Drip Free Quick Coupler

brake couplers.

Not needed for factory setup units.

Male Coupler

9/16 Wrench

3”

14

Содержание Kar-Kaddy SS KK460SS

Страница 1: ...1 7 06 RD20010 Rev 6...

Страница 32: ...32 NOTES...

Страница 34: ...34 Postage Dethmers Manufacturing Company 4010 320th Street Box 189 Boyden Iowa 51234...

Страница 35: ...35 NOTES...