Page 8

Reduced gas flow rate setting for taps

1. Ignite the burner that is to be adjusted and

turn the knob to the reduced position.

2. Remove the knob from the gas tap.

3. Use an appropriately sized screwdriver to

adjust the flow rate adjustment screw. For

LPG (Butane - Propane) turn the screw

clockwise. For natural gas, you should turn

the screw

counter-clockwise

once. The

normal length of a straight flame in the

reduced position should be 6-7 mm

4. If the flame is higher than the desired position,

turn the screw clockwise. If it is smaller turn

anticlockwise.

5. For the last control, bring the burner to both

the high-flame and reduced positions and

check whether the flame is on or off.

Depending on the type of gas tap used in your

appliance the adjustment screw position

may

Routing of the gas hose

Before connecting the gas hose, make sure that

the gas hose outlet behind the product is in the

same direction as the hose outlet

3

3

X

X

X

•

“A”

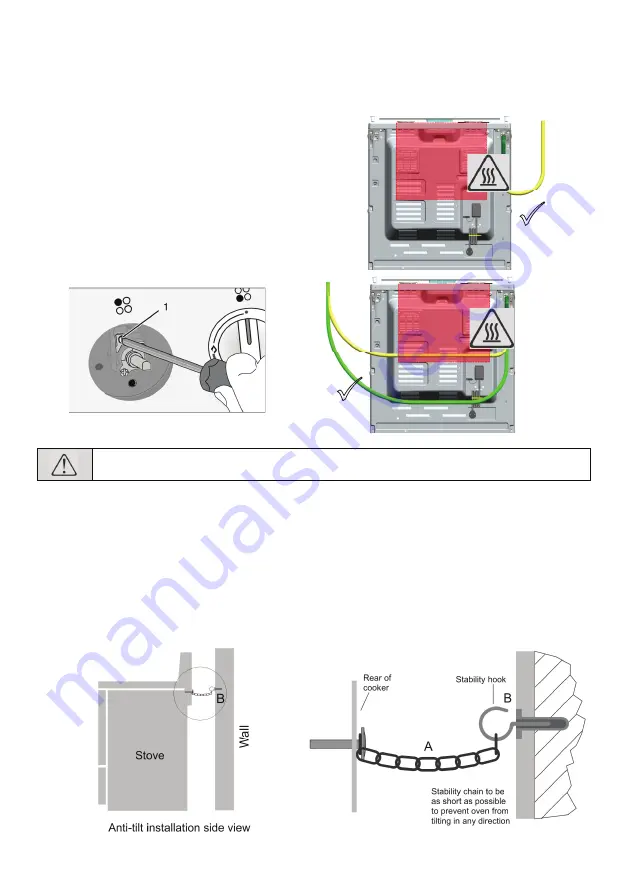

1 x Stability chain

•

“B”

1 x Stability hook with anchor sleeve

•

“A”

is factory fitted at the rear of the stove in

the centre. (See overleaf for instructions if the

removable splashback is to be fitted)

•

Position the stove and move

“A”

to touch the

wall behind the stove.

•

Mark the hole where

“A”

touches the wall

behind the stove.

•

Move the stove away from the wall to allow for

an area to work in.

All stoves can tilt if you or a child sit or lean on an open oven door. Safety regulations

stipulate that the ANTI-TILT mechanism supplied with the stove, must be fitted as shown.

•

Using a 8.0 mm concrete bit, drill a hole at

the marked position.

•

Using the Stability hook and anchor sleeve

“B”

, firmly secure

“B”

to the wall.

•

Slide the stove back in position and engage

the stability chain

“A”

onto the Stability hook

“B”

.

•

The stove is then secured and will not

accidentally tilt if downward pressure is

applied to the open oven door.

Anti-tilt mechanism