7

turning the hex bullet foot to the

required height.

c.

Rigid Casters (Only):

1. Install the optional rigid casters on the

fryer rear channel only.

2. Do not use more than two metal shims

per caster.

3. There are no thread adjustments for the

rigid casters.

d.

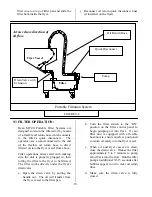

If the floor is uneven or has a decided

slope, it is recommended to place the fryer

on a smooth platform. Do not rely on

leg thread or caster shims for

adjustments.

e.

If the fryer is moved, re-level the fryer

following the instructions given in

Steps 3.3.a-c.

f.

This fryer must be restrained to

prevent tipping when installed in order

to avoid the splashing of hot liquid.

The means of restraint may depend on

the type of application, such as

connecting to a battery of appliances

or installing the fryer in an alcove, or

by separate means, such as restraining

devices. A bracket has been provided

on the fryer back panel for this

purpose.

The install must be reviewed at the

time of installation to ensure it

meets the intent of these

instructions. The on-site supervisor

and/or operator(s) should be made

aware that there is a restraint on the

appliance and, if disconnection of

the restraint is necessary, to

reconnect this restraint after the

appliance has been returned to its

originally installed position.

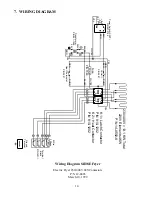

3.4 ELECTRICAL CONNECTIONS:

Plan and carry out installation in

accordance with local codes.

a.

Connections: Connections to the

terminal block and grounding lug

should be made through the hole

provided for this purpose in the

junction box. To install this fryer, the

servicer/installer must use a goose

neck and retainer to protect the cord

set.

b.

Wiring Diagram: It is attached to the

inside of the fryer door. Amperage for

each unit depends on the type of

installation and accessories supplied

with the unit. A 230/400V Wiring

Diagram is provided in Chapter 7 also.

Adjust leg height with an

adjustable wrench.

Figure 3-2

WARNING!

DO NOT USE MORE THAN

TWO METAL SHIMS PER

LEG/CASTER

.

USING MORE THAN TWO

SHIMS PER LEG/CASTER

MAY CAUSE THE FRYER TO

BECOME UNSTABLE, TIP

OVER, AND MAY CAUSE

INJURY TO THE OPERATOR.