De Gier B.V., Westlandseweg 9, 2291 PG WATERINGEN, THE NETHERLANDS,

+31 (0)174 292089, [email protected], www.degierdrivesystems.com

Versie 1 – 2020 / 03 / 01

21

9. Troubleshooting

Troubleshooting may only be performed by qualified staff (see paragraph 1.3).

Mortal danger! Mortal danger due to electrical or mechanical forces!

Before starting to work on the motor gearbox and associated parts, always disconnect the power supply by

means of the main or isolation switch and secure it against re-activation by using a padlock.

9.1 Malfunction: power failure

• Interrupt the power supply to prevent unintentional starting of the motor gearbox during work activities.

• In emergencies the motor gearbox can be moved to the desired position using an electric drill and a hexagonal bit

inserted in the hex socket on the electric motor shaft.

Caution!

When driving the electric motor by means of a hexagonal tool, a maximum speed of 250 RPM should be

observed to protect the hexagonal socket on the rear of the electric motor shaft.

9.2 Malfunction: drive does not start

• Check the motor protection switch and its settings. If the malfunction occurs again, this may indicate overload.

• Check whether one of emergency limit switches of the motor gearbox is actuated.

• Check the electrical connections, including the connection of the limit switch.

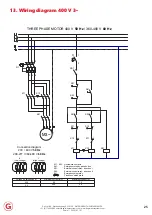

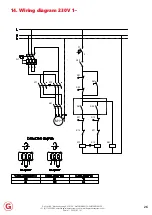

• For motor gearboxes with 3-phase mains supply check whether rotation direction “I”/”II” corresponds with limit

switches “S11” and “S12”.

• If the thermal protection (bi-metal switch) of the motor gearbox has tripped, the motor gearbox must be left to cool

down for approximately 20 minutes. After this time the motor gearbox can be used again. If this protection trips

repeatedly, contact your installer to resolve this problem.

9.3 Malfunction: end-position passed

• Check whether all the set screws in the limit switch system are tight and check the setting of the limit switches.

• Re-adjust the limit switch if necessary (see chapter 4.5).

• Check the operation of the working limit switches “S11” and “S12” and emergency limit switches “S21” and “S22”.

The switches must be wired and monitored as normally closed (NC) contacts.

• Check the operation of the relay and replace it if necessary.

9.4 Malfunction: loss of oil

• Check whether the correct venting screw has been removed, see chapter 4.1.

• Check whether a correct installation position is being applied.

• Contact your installer in case of oil loss.

9.5 Malfunction: buzzing noise from electric motor

• Check the voltage over all three phases, these must be equal and correspond with the value on the type plate of the

electric motor.

• Check whether all nuts on the terminal strip of the electric motor have been properly tightened.

• Contact the installer if the malfunction remains.

9.6 Screen cloth does not roll up evenly (excessive folding of cloth or foil)

If the screen cloth (or foil) does not roll up evenly, it is possible that the weight of the motor gearbox causes the cloth to

sag. This can be resolved by applying a counter-weight or mounting a strip of Dacron tape right next to the GXP10. This

non-stretching tape will then carry the weight of the motor gearbox and is rolled up simultaneously with the screen cloth.