13

/

14

WWW.DDTOP.COM

8. Precautions

8.1 The density of use should be the same as the design density. If the density changes, please contact the factory

to confirm whether it can continue to be used.

8.2 Make sure the power supply is safe and reliable, and must be powered off before opening the cover.

8.3 When the vibration is large, it is not suitable to use the float level switch.

8.4 Medium with viscosity ≥500mPa/s is not suitable for use with float level switch.

8.5 Medium with ferromagnetic particles is not suitable for use with float level switch.

8.6 After wiring, tighten the power supply cover to prevent the instrument from getting wet.

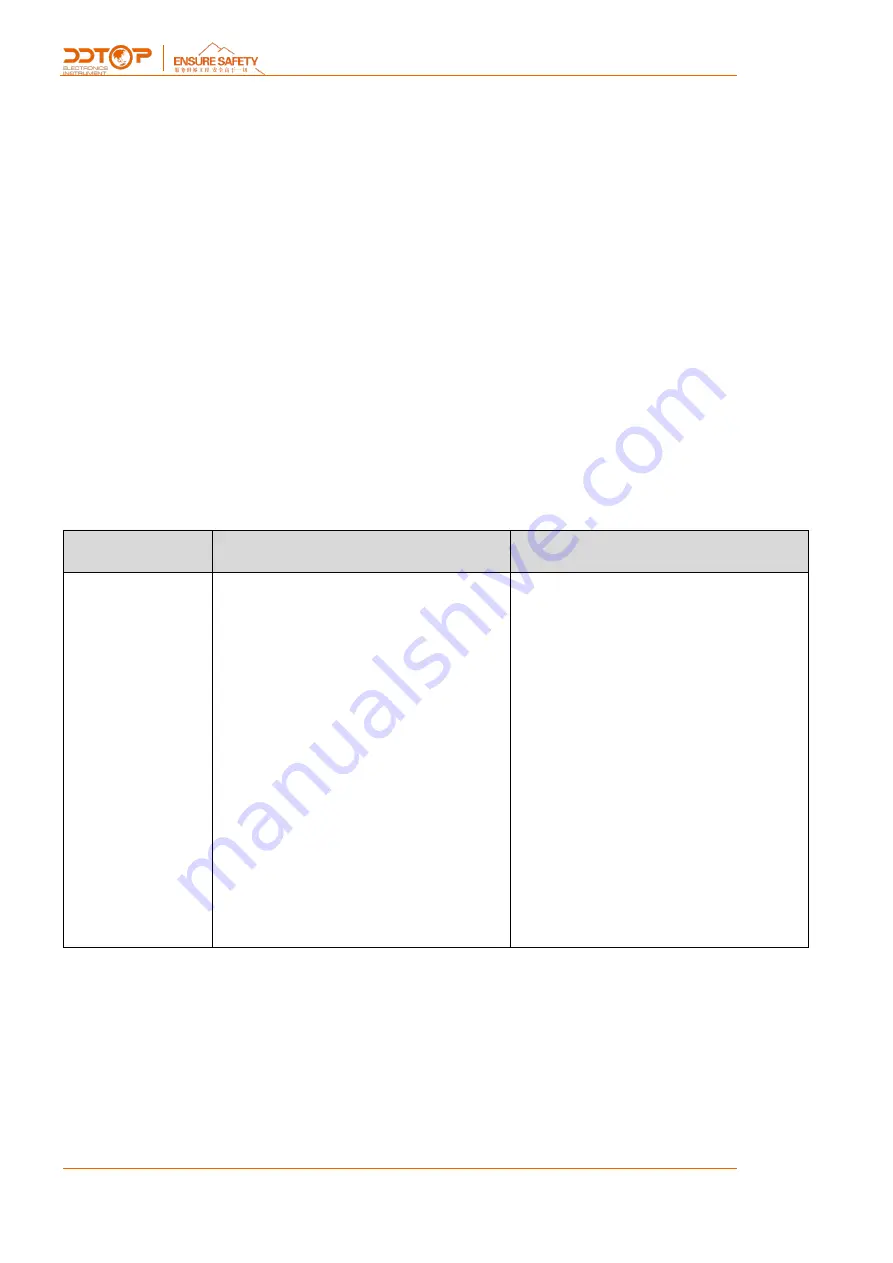

9. Fault Analysis and Elimination

Fault Phenomenon

Cause of Issue

Troubleshooting Method

The level to the

specified position

switch does not work.

1. The ball is too heavy, not floating.

2. The installation location is wrong.

3. The lead pipe is too long, the float ball is

stuck in the lead pipe and does not

reach into the tank.

4. Ferromagnetic particles or obstacles in

the medium cause the float ball to

block.

5. Transmitter failure.

6. Self-checking level controller handle

position is wrong.

1. Confirm the density or replace the float.

2. Confirm the installation position

according to the instructions, and make

sure the wiring is punched down.

3. Confirm that the order neck is larger than

the length of the guide tube. If the neck

is small, contact the factory to replace

the relevant parts.

4. Remove the instrument to clean the float

and connecting rod.

5. Replace the transmitter.

6. The handle position is moved to the

working position.