17

The taper and the fit of the cone make a significant difference in accurate centering. Cones having a low taper fit the hub bore and guide

the wheel for better centering during the mounting process.

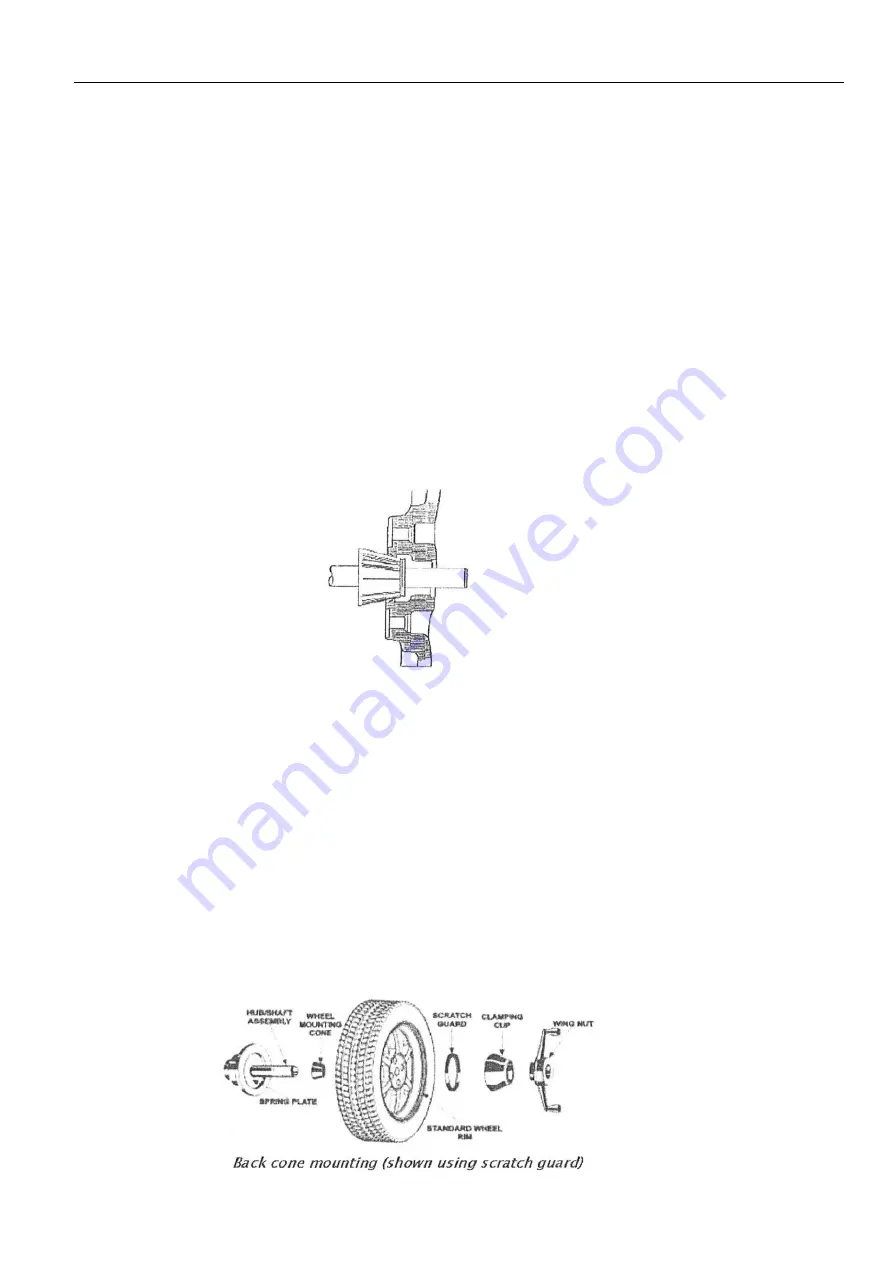

Most wheels benefit with the cone mounted from the backside. This method is referred to as back cone mounting.

CHECK FOR:

✓

Correct mounting cone/adaptor for this wheel design

✓

Wheel defect such as metal burr interfering with the cone/adaptor

✓

Dirt or debris interfering with the cone/adaptor

BACK CONE MOUNTING PROCEDURE

Select the proper wheel-mounting cone by placing it in the center bore of the wheel to be balanced.

Select the cone that contacts the wheel nearest the center of the cone.

Place the wheel-mounting cone on the spindle against the spring plate. Mount the wheel with the inner rim facing the balancer and

centered on the cone.

Install the clamping cup and wing nut on the spindle shaft against the wheel and secure the entire assembly by firmly tightening the

wing nut. Depress the foot pedal to hold the spindle in place (if available). Slowly roll the wheel toward you during the initial tightening

of the wing nut. This helps the wheel to roll up the taper of the cone as opposed to forcing it to slide up the cone.