5

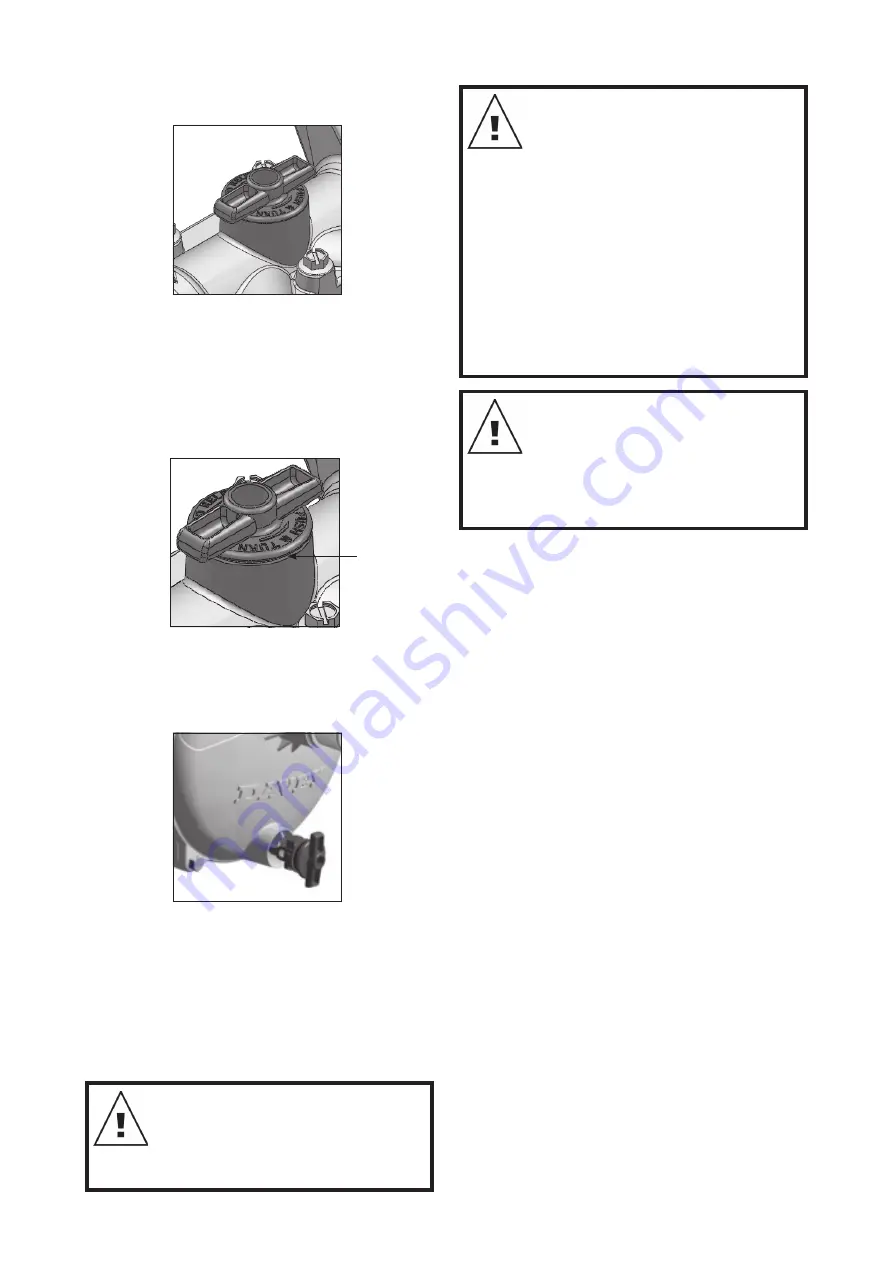

• Insert the plug and then rotate ¼ turn clockwise as

shown in

figure 1.3

.

Figure 1.3

• Once the pump is pressurized the plug will pop

up slightly engaging the security latch (

figure

1.4

), thus preventing accidental removal. While

the plugs can be removed under pressure, the

operator must intentionally push the plug in and

then, whilst still holding the plug in, twist counter-

clockwise on the plug. It is possible to abort plug

removal part way through the process.

Figure 1.4

Gap

1.5 Drain plug

The drain plug fitment is like the priming plug.

However, to insert the drain plug the plug handles

start in the vertical position as shown in

figure 1.5

.

Figure 1.5

Keep the plug and it’s surround free from sand and

grit. Occasionally apply a suitable silicon-based

rubber grease (petroleum-based greases are not

acceptable) to the o-ring. The Firefighter pump drain

plug is identical in operation. Both plugs are available

with a 1/4” BSP taping to facilitate the fitment of

pressure gauges or automatic drain valves etc.

2. PUMP WARNINGS

ATTENTION: The Firefighter pump

may contain hot liquid under

pressure. The Firefighter pump body

should always be full of water when

operating and must not be allowed to

run dry for extended periods.

IMPORTANT: Check that there is

water flow through Firefighter pump

when running, as insufficient flow

can cause damage, not covered by

warranty. If a Firefighter pump has

been allowed to run at closed (or

“dead”) head, do not open any valves

of priming plugs until the pump

casing has cooled.

When transporting your Firefighter

pump, water from the casing may leak

back past the priming flap. Before

attempting to self-prime the Firefighter

pump you may need to check that the

casing is still full of water.

ATTENTION: In the event of fire

damage to the Viton elastomers

(“rubber”), consult your Davey dealer

regarding safe handling of burnt

Viton components. Burnt Viton emits

a dangerous acid, which can cause

serious health effects.

3. CARE AND MAINTENANCE

3.1 Pump and pipework

Run the pump every week or so during the fire

season to ensure it and associated pipework and

fittings are in good working order. This will also help

turnover the fuel and make sure the lubricating oil

is circulated around the engine. Ensure the water

source is free of leaves and sticks etc. which may

block inlet strainers and obstruct the water flow to

the pump.

Check for pipe leaks and the correct operation of

all valves connecting the Firefighter pump to the

water source and on the discharges. Air leaks on

the suction line are the number one cause of pump

problems. Make sure all rubber gaskets and seals

are in good order.

3.2 Pump operation

High performance can be obtained from a Firefighter

pump if the engine speed is increased. However,

we do not recommend the Firefighter pump be

operated over 3,600rpm for extended periods, as

this may overload the engine and reduce its working

life. Operating the engine at full throttle for extended

periods will shorten engine life and may result in

premature failure. For operations such as irrigation

or dam and tank filling, the throttle should be closed

to around 3/4 maximum. This should correspond to

around 3,000rpm. The exception to this is the diesel

models 5148Y, 5248YEV and 5210YE/HP. These

models are continuously rated to 3,600rpm.

Note: special consideration applies to 5150P and

5250P models. See section 4.7.

Содержание Firefighter 5148YEV

Страница 26: ...26 NOTES...

Страница 27: ...27...