10

www.danvex.fi

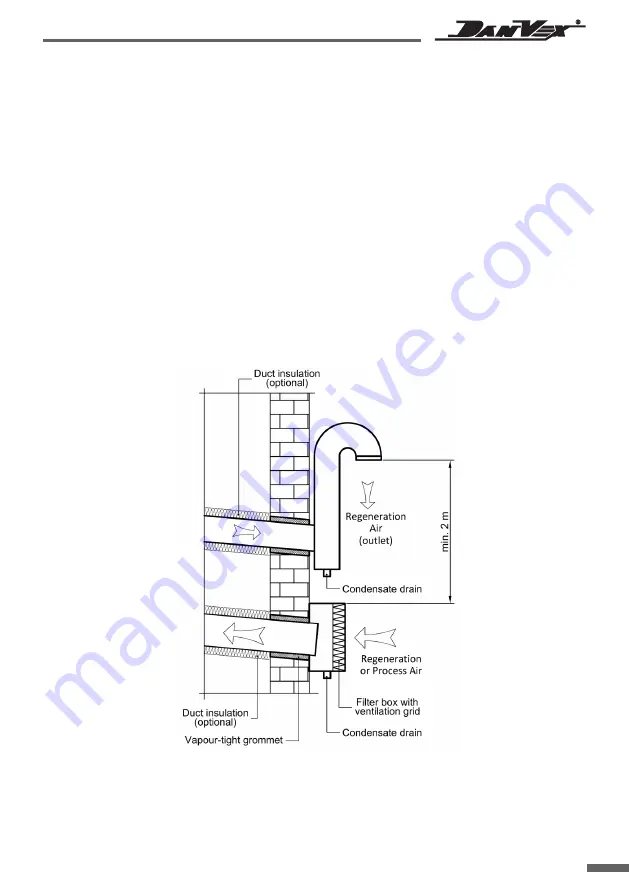

3.7 Duct connection

The size of the process air and regeneration air ducts should meet the recommended values of

ISO 7807. For the installation of duct joints of ducts and elbow flanges, the bolt length shall not

exceed 20 mm. When instaling the inlet and outlet connecting ducts of the unit, the following

suggestions should bе paid attention to:

• Minimize the length of the air duct in order to reduce the static pressure loss of the air

system;

• ln order to ensure performance, all rigid (galvanized) duct connections must bе airtight;

• The duct should bе insulated to avoid condensation оn the outer wall of the duct when

the temperature of the airflow in the duct drops below the dew point temperature of the

outside air, which will lead to duct corrosion and energy loss саn bе avoided;

• The ductline directly installed оn the unit should bе fully supported in order to reduce the

load and pressure caused bу the gravity and operation of the ductline;

• ln order to reduce noise and vibration along the ductline, the regeneration air outlet саn

bе installed with а soft connection with good quality and strong air tightness.

If the system is introduced into the dehumidification unit from the outside, the air inlet should

bе sufficiently high from the ground to prevent the inhalation of dust and debris. The entrance

must bе far away from possible pollution sources, such as energy waste gas, steam and harmful

gases. ln order to prevent humid air from humidifying the process air (inlet), the outdoor process

air inlet must bе at least 2 meters away from the humid air outlet. The ductline design should

prevent the intrusion of rain and snow.