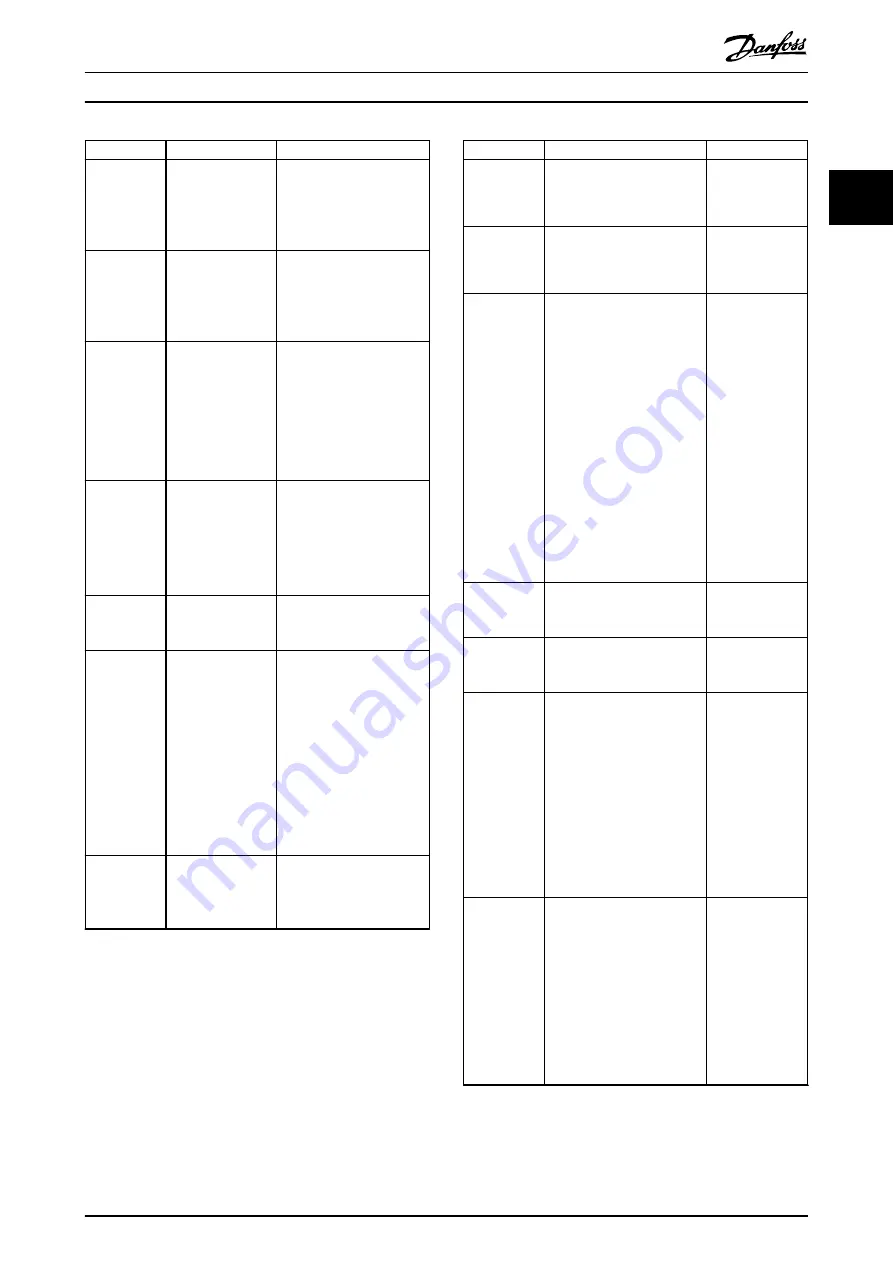

Function

Description

Limits/errors

AUX

overvoltage

When the AUX

voltage rises above

a certain level, a

warning/error is

issued.

•

Warning: >53 V

•

Error: >56 V

AUX

undervoltage

When the AUX

voltage drops

below a certain

level, a warning/

error is issued.

•

Warning: <21.6 V

•

Error: <19 V

AUX

overcurrent

When the AUX

current rises above

a certain level, a

warning/error is

issued.

•

Warning: >90% of user-

defined limit

•

Error: >100% of user-

defined limit

The default value of

15 A is used if no limits

are defined by the user.

Brake error

The SAB reports

various brake-

related errors.

•

Shorted brake resistor

•

Shorted brake IGBT

•

Thermal overload

•

Disconnected brake

resistor

Inrush fault

The SAB can handle

up to 2 inrush

cycles per minute.

Error issued if >2 inrush

cycles occur per minute.

Mains phase

loss

The SAB detects

the mains phase

loss and issues a

warning/error when

limits are reached.

•

Warning: 3–10% mains

phase imbalance

•

Error:

-

>10% mains

phase

imbalance

-

3–10% mains

phase

imbalance for

>10 minutes

STO 1 & STO

2 indicators

The SAB indicates

the presence of the

STO 1 & STO 2

voltage.

LED on: STO deactivated

LED off: STO activated

Table 2.10 Additional Protection Features for SAB

2.10.5.2 VLT

®

Integrated Servo Drive

ISD 510

The VLT

®

Integrated Servo Drive ISD 510 has the additional

protection features detailed in

.

Function

Description

Limits/errors

UDC

overvoltage

When the DC-link voltage

rises above a certain level, a

warning/error is issued.

•

Warning:

>810 V

•

Error: >820 V

UDC

undervoltage

When the DC-link voltage

drops below a certain level, a

warning/error is issued.

•

Warning:

<410 V

•

Error: <373 V

Overcurrent at

output

To protect the servo drive

and any machinery attached

to the servo drive shaft, a

current limit protection is

implemented. The current

limit protection on the servo

drive is available for motor

phase current. All 3 phase

currents are constantly

monitored. If an overcurrent

occurs, the servo drive stops

the actual operation. The

servo drive stops the shaft

rotation, engages the brake

(if present), and an error is

issued.

•

Size 1: >8 A

•

Size 2: >9 A

Motor

position

CRC check of each encoder

value, resolver amplitude, and

consistency check.

–

Brake control The brake current is

controlled by the servo drive

firmware.

–

Maximum

shaft speed

The shaft speed of each

servo drive type is limited to

protect the motor mechanical

parts.

Maximum motor

speed:

•

Size 1, 1.5 Nm:

7000 RPM

•

Size 2, 2.1 Nm:

6000 RPM

•

Size 2, 2.9 Nm:

5000 RPM

•

Size 2, 3.8 Nm:

4000 RPM

Torque limit

The application peak torque

limit [M

max

] can be set via

parameters

52-15

,

52-23

, and

52-36 Application Torque Limit

(0x2053)

.

The maximum torque per

servo drive is calculated as:

Maximum phase current x

torque factor

Peak torque M

max

:

•

Size 1, 1.5 Nm:

6.1 Nm

•

Size 2, 2.1 Nm:

7.8 Nm

•

Size 2, 2.9 Nm:

10.7 Nm

•

Size 2, 3.8 Nm:

12.7 Nm

Table 2.11 Additional Protection Features for ISD 510

Servo Drive

System Overview

Design Guide

MG36C102

Danfoss A/S © 08/2017 All rights reserved.

25

2

2