Application guidelines

37

FRCC.PC.021.A5.22

System design recommendations

Oil equalisation

Suction gas in a hermetic compressor flows via

the oil sump which makes it more difficult to

maintain equal pressure in the sumps of parallel

compressors. Since oil equalisation usually

depends on equal sump pressures this is a

point of special attention. Danfoss Commercial

Compressors has developed specially adapted

oil equalisation systems which ensure proper oil

balancing between the manifold compressors

but it is always recommended to carry out

some tests to validate effective operation and

oil equalisation of compressors in parallel

installation at any operating conditions of final

application.

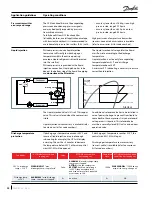

Test conditions

Tests shall be done at three points in final

application envelope:

ARI-based conditions

Low evaporation (SH18°F): low flow rate / pure

oil/ low oil level

High load (SH18°F): high flow rate/ diluted oil/

high oil level

Low

evaporation

ARI

condition

High

load

Test sequences

Continuous for all compressors: 100% charge

(all compressors continuous running)

Continuous with partial charge: all partial

charges configuration must be tested

On/Off test: after 2 minutes shutdown of any

compressor, the oil level has to retrieve a proper

oil level within 1 minute when the compressor is

switched back on.

Transient 100% load: in transient condition such

as end of defrost with temporary liquid flood

back, check that oil return to normal level.

Oil level criteria

The oil level of running compressors must

be visible or full in the sight glass of running

compressors at all operating conditions

described before.

The oil level of idle compressors may disappear

in the oil sight glass.

The oil level must retrieve a visible level in all

compressors after the unit is stopped.

Oil level top up might be necessary to retrieve

a visible oil level in the sight glasses. Always

use a Danfoss oil from new can (see section

accessories).

On units working 100% load continuously, a

compressor oil level might decrease. In order

to avoid any loss of oil, regular unit stops might

be needed to re equilibrate oil levels in the

compressors.

above the saturated discharge temperature, this

indicates liquid flood back.

Continuous liquid flood back can occur with

a wrong dimensioning, a wrong setting or

malfunction of the expansion device or in case of

evaporator fan failure or blocked air filters.

A suction accumulator providing additional

protection as explained hereunder can be used

to solve light continuous liquid flood back.

Suction accumulator:

a suction accumulator

offers protection against refrigerant flood back

at start-up, during operations or defrosting by

trapping the liquid refrigerant upstream from

the compressor. The suction accumulator also

protects against off-cycle migration by providing

additional internal free volume to the low side of

the system.

A suction accumulator must be carefully

dimensioned, taking into account the refrigerant

charge as well as the gas velocity in the suction

line.

The accumulator should not be sized for less than

50 % of the total system charge. Tests must be

conducted to determine the actual refrigerant

holding capacity needed for the application

.

Depending on the operating conditions it may

happen that the recommended connections of

the accumulator are one size smaller than the

suction line.

Содержание PSH051-4

Страница 1: ...Danfoss scroll compressors PSH051 to 077 50 60 Hz R410A Application guidelines http danfoss us com...

Страница 2: ......

Страница 3: ......

Страница 58: ......

Страница 59: ......