180R9288_AQ109686503100en-001301 | 45

© Danfoss | 2023.12

Operation guide

Installation, Operation and Maintenance Manual for PAHT 20-90 pumps

Systems can be either:

•

Water hydraulic systems, in which the water

is recirculated back to tank.

•

Open-ended systems with water supply

from a tank.

•

Open-ended systems with direct water-

supply (boosted pressure).

The design of the system must ensure that

selfemptying of the pump during standstill is

avoided.

The minimum boost pressure is 2 barg (29 psig)

and the maximum peak pressure is 20 barg

(290 psig). The recommended normal boost

pressure is 2-6 barg (29-87 psig) (3-7 barg

[43.5-101.5 psig] abs).

1. Identification

Protective cap must be removed

and thrown away before usage.

2.

System design

2.1 Closed water hydraulic systems, water

recirculated

In order to eliminate the risk of cavitation, always

ensure a minimum inlet pressure of 0 barg

(0 psig) (1 barg [14.5 psig] abs) by observing the

following guidelines:

.

If it is unknown what the peak inlet pressure can

be, then there should be a 15 barg (218 psig)

safety relief valve on the inlet side of the pump.

Note: All mentioned pressures refer to

measures in the respective pump gauge ports.

The inlet pressure of the pump must never

exceed the outlet pressure. This may typically

occur in boosted or open-ended systems with

supply direct from the tap and where a bypass

valve is activated.

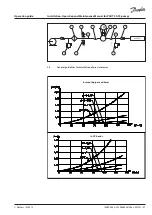

2.2 Closed-system design

A

Inlet line:

Dimension the inlet line to obtain mini-

mum pressure loss (large flow, minimum

pipe length, minimum number of bends/

connections, and fittings with small

pressure losses).

B

Inlet filter:

Install the inlet filter (1) in front of the tank

(2). Place the tank above pump and pump

inlet. Please consult the Danfoss filter data

sheet for guidance on how to select the

right filter.

C

Monitoring pressure switch:

Install the monitoring pressure switch (3) in

front of the filter (1). Set the maximum inlet

pressure to 2 barg (29.0 psig). The monitor-

ing pressure switch will stop the pump (5) if

inlet pressure is higher than 2 barg

(29.0 psig), indicating that the filter element

must be changed.

D

Monitoring temperature switch:

Install the monitoring temperature switch

(4) in the tank. Set the temperature value

according to technical data, item 4. The

monitoring temperature stops the pump if

inlet temperature is higher than the set

value.

E

Hoses:

Always use flexible hoses (6) to minimize

vibrations and noise.

F

Inlet pressure:

In order to eliminate the risk of cavitation

and other pump damage, pump inlet

pressure must be maintained according to

specifications described in item 4, technical

data.

G

Non-return valve (7):

Should be installed after the outlet to

prevent pump backspin, which may ruin

the pump.

H

Pressure relief valve:

As the Danfoss PAHT pump begins to

create pressure and flow immediately after

start-up regardless of any counter pressure,

a pressure relief valve (8) should be

installed to prevent system damage.

I

System water filling:

To ensure proper filtration of new water

(10) supplied to the system, always use the

filling valve (9).

J

Minimum level switch:

Install the minimum level switch (11) above

the outlet of the reservoir. The level switch

must stop the pump if the water in the

reservoir is below the switch, which

indicates that the reservoir is empty.