180R9288_AQ109686503100en-001301 | 21

© Danfoss | 2023.12

Operation guide

Installation, Operation and Maintenance Manual for PAHT 20-90 pumps

2. Benefits

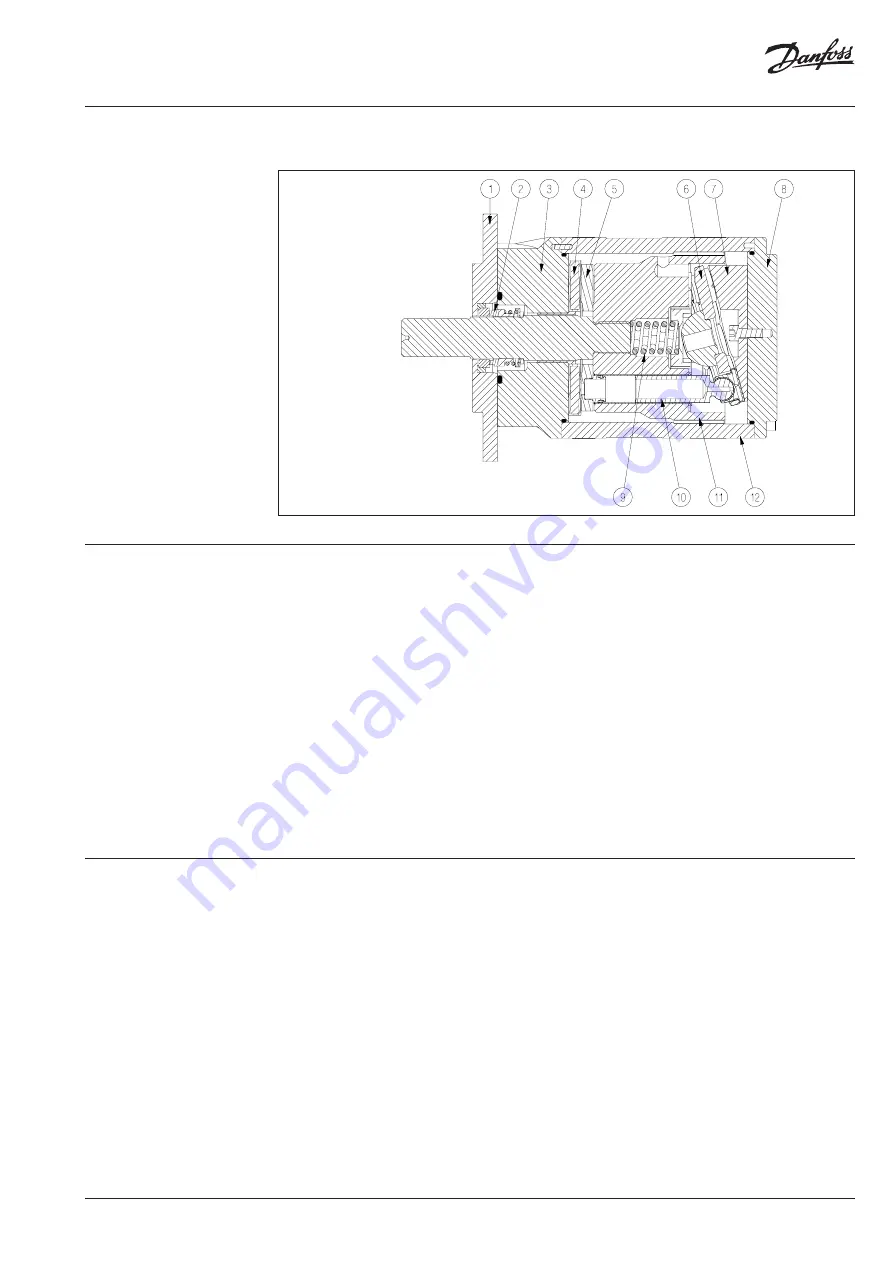

Below sectional drawing is an example of a PAHT pump.

3. Application

examples

1: Mounting flange

2: Shaft seal

3: Connecting flange

4: Port plate

5: Valve plate

6: Retainer plate

7: Swash plate

8: End cap

9: Spring

10: Piston

11: Cylinder barrel

12: Housing with bearing

•

Zero risk of lubricant contamination:

-

Oil lubricants are replaced with the

pumped medium, water, so there is no

contamination risk from the pump.

•

Low maintenance costs:

-

Efficient design and all-stainless steel

construction ensure exceptionally long

lifetime. When Danfoss specifications

are met, service intervals of up to 8,000

hours can be expected. Service is easy,

and can be carried out on site due to

the simple design and few parts.

•

Low energy costs:

-

The highly efficient axial piston

design provides the lowest energy

consumption of any comparable pump

on the market.

•

Easy installation:

-

The lightest and most compact design

available.

-

Pump can be installed horizontally or

vertically.

-

No pulsation dampeners necessary due

to extremely low-pressure pulsation.

-

Powered by electric motors or

combustion engines.

-

Suitable for both boosted inlet pressure

and water supply from a tank.

-

No need for cooling circuits due to very

high mechanical efficiency.

•

Certified quality:

ISO 9001, ISO 14001

API available on request

•

High-pressure cleaning with ultra-pure water, as

used in the manufacturing of flat-panel displays

and many other electronic products.

•

High-pressure cleaning with ultra-pure water,

as used in the manufacturing of parts for the

automobile industry.

•

Adiabatic cooling systems to replace or

supplement standard A/C systems in server

rooms and factories.

•

Humidification in office buildings, electronic

component manufacturing, dairies,

greenhouses, etc.

•

Dust suppression and odor control systems, for

example in paper, textile and wood production.

•

Reduction of NOx emissions in diesel engines

and gas turbines.

•

Gas turbine by inlet fogging and fuel wash

systems.