LUBRICATION

ADJUSTING AIR PRESSURE

CONNECTING AIR SUPPLY

TOOL TESTING

NAIL LOADING

REMOVING NAILS

METHODS OF OPERATION

COLD WEATHER OPERATION

ADJUSTABLE THE EXHAUST

TRIGGER LOCK

SPECIFICATION

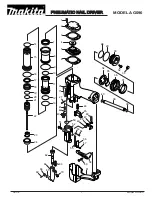

FEATURES

WORK AREA

PERSONAL SAFETY

TOOL USE AND CARE

SERVICE

AIR SOURCE

CONTENTS:

CLEANING

STORAGE

HOOKUP INSTRUCTIONS FOR TOOL TO AIR SUPPLY

IMPORTANT INFORMATION

EXPLANATION OF THE NAILING ACTION

GENERAL SAFETY RULES

DESCRIPTION AND SPECIFICATION

ASSEMBLY/INSTALLATION

OPERATION

MAINTENANCE

RECOMMENDED HOOKUP

TROUBLE SOLVING

P1

P1

P1

P1

P1

P1

P2

P2

P3

P3

P4

P4

P4

P4

P4

P4

P5

P5

P6

P7

P7

P7

P8

P8

P8

P8

P8

P8

P9