Test Operation

Si39-504

106

Test Operation

1.

Test Operation

1.1

Procedure and Outline

Follow the following procedure to conduct the initial test operation after installation.

1.1.1 Check work prior to turn power supply on

Check on refrigerant piping /

insulation materials

Check airtight test and vacuum

drying.

Check on amount of refrigerant

charge

Check the stop valves for

conditions.

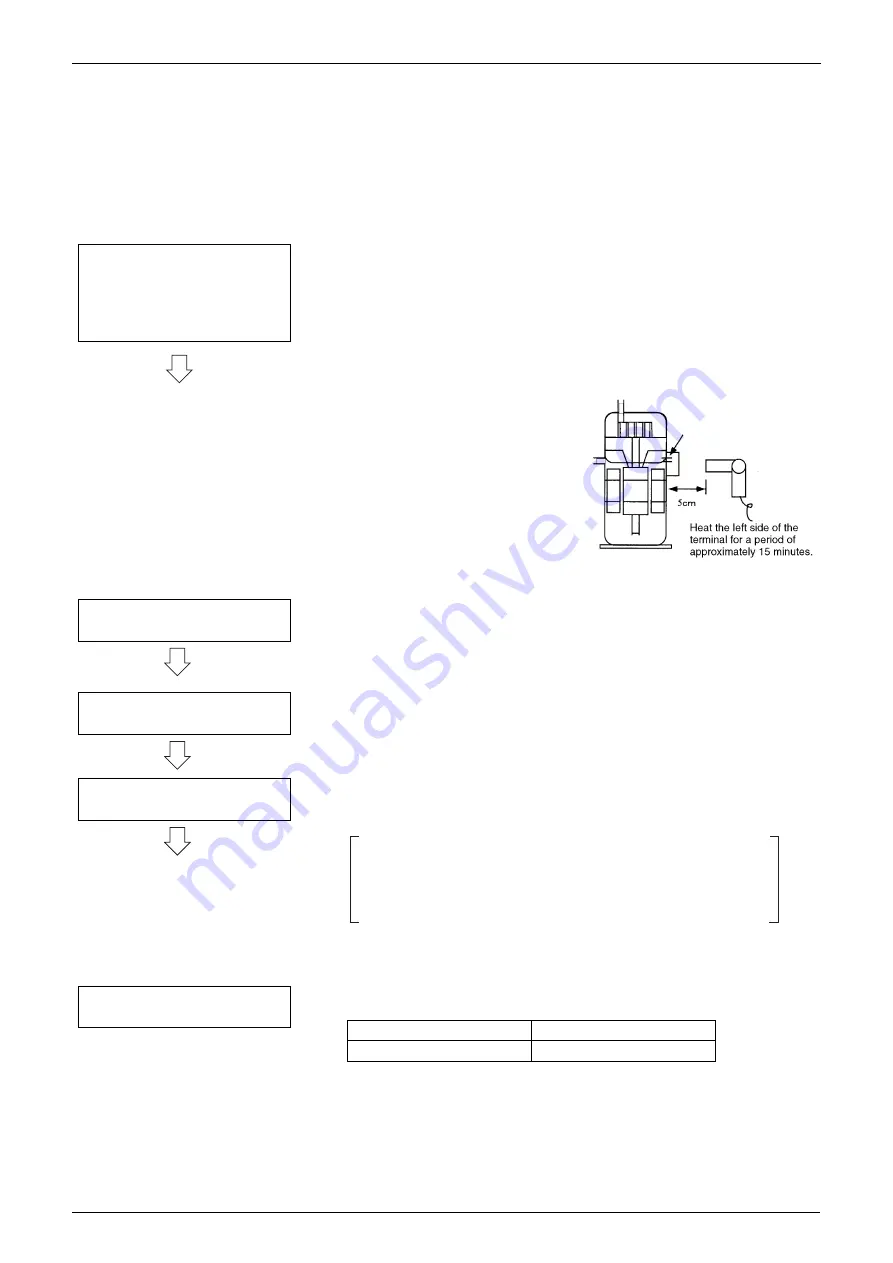

Terminal

Dryer

(1000W)

Check the below items.

2

Power wiring

2

Control transmission wiring

between units

2

Earth wire

¡

Is the wiring performed as specified?

¡

Is the designated wire used?

¡

Is the wiring screw of wiring not loose?

¡

Is the grounding work completed?

¡

Is the insulation of the main power supply circuit deteriorated?

Use a 500V megger tester to measure the insulation. (*1)

2

Do not use a megger tester for other circuits than 200V (or

240V) circuit.

*1:Measure to be taken against decreased insulation resistance in

the compressor

If the compressor is left to stand for

an extended period of time after the

refrigerant charge with the stop valve

open and the power supply OFF, the

refrigerant may be mixed in the

compressor, thus decreasing the

insulation resistance.

Heat the compressor as shown on

the right and then recheck the

insulation.

¡

Is the pipe size proper?

¡

Is the pipe insulation material installed securely?

Liquid and gas pipes need to be insulated. (Otherwise causes

water leak.)

¡

Have the airtight test and the vacuum drying been conducted

according to the procedure in the Installation Manual?

¡

Has a proper amount of refrigerant been charged according to the

result of the "Calculation of the refrigerant additional charging

amount"?

Charge refrigerant in the liquid state from the service port of the

liquid-side stop valve, with stopping the outdoor unit after the

completion of vacuuming.

If the total amount of refrigerant calculated cannot be charged,

follow information in "Additional charging of refrigerant" on the

following page to charge the refrigerant by the deficient amount.

¡

Has the refrigerant additional charging amount been recorded on

the "Service Precautions" label?

¡

Check to be sure the stop valves are under the following

conditions.

Liquid-side stop valve

Open

Gas-side stop valve

Open

Содержание VRV II RXYQ5MATL

Страница 20: ...Si39 504 Specifications 9 Part 2 Specifications 1 Specifications 10 1 1 Outdoor Units 10 1 2 Indoor Units 21...

Страница 53: ...Specifications Si39 504 42 Specifications...

Страница 56: ...Si39 504 Refrigerant Circuit Refirgerant Circuit 45 RXYQ5MA 3D048203 2 4 3 5 K J S E D M T N P A G O 1 W V...

Страница 115: ...Outline of Control Indoor Unit Si39 504 104 Function...

Страница 161: ...Field Setting Si39 504 150 Test Operation...

Страница 172: ...Si39 504 Troubleshooting by Remote Controller Troubleshooting 161...

Страница 265: ...Piping Diagrams Si39 504 254 Appendix 1 Piping Diagrams 1 1 Outdoor Unit RXYQ5MAYL E TL E 3D048203...

Страница 266: ...Si39 504 Piping Diagrams Appendix 255 RXYQ8MA 10MA 12MAYL E TL E 3D048033A...

Страница 267: ...Piping Diagrams Si39 504 256 Appendix RXYQ14MA 16MAYL E TL E 3D048034A...

Страница 271: ...Wiring Diagrams for Reference Si39 504 260 Appendix RXYQ8MA 10MA 12MAYL E 3D047088C...

Страница 272: ...Si39 504 Wiring Diagrams for Reference Appendix 261 RXYQ14MA 16MAYL E 3D047089C...

Страница 273: ...Wiring Diagrams for Reference Si39 504 262 Appendix 2 1 2 RXYQ MATL E RXYQ5MATL E 3D049059A...

Страница 274: ...Si39 504 Wiring Diagrams for Reference Appendix 263 RXYQ8MA 10MA 12MATL E 3D049060A...

Страница 275: ...Wiring Diagrams for Reference Si39 504 264 Appendix RXYQ14MA 16MATL E 3D049061A...

Страница 277: ...Wiring Diagrams for Reference Si39 504 266 Appendix RXYQ18MA 20MA 22MA 24MA 26MA 28MA 30MA 32MAYL E 3D040747H...

Страница 278: ...Si39 504 Wiring Diagrams for Reference Appendix 267 RXYQ34MA 36MA 38MA 40MA 42MA 44MA 46MA 48MAYL E C 3D040748H...

Страница 279: ...Wiring Diagrams for Reference Si39 504 268 Appendix 2 2 2 RXYQ MATL E RXYQ5MA 8MA 10MA 12MA 14MA 16MATL E 3D041990A...

Страница 280: ...Si39 504 Wiring Diagrams for Reference Appendix 269 RXYQ18MA 20MA 22MA 24MA 26MA 28MA 30MA 32MATL E 3D041991A...

Страница 281: ...Wiring Diagrams for Reference Si39 504 270 Appendix RXYQ34MA 36MA 38MA 40MA 42MA 44MA 46MA 48MATL E 3D041992A...

Страница 282: ...Si39 504 Wiring Diagrams for Reference Appendix 271 2 3 Indoor Unit FXCQ20M 25M 32M 63MVE 3D039556A...

Страница 283: ...Wiring Diagrams for Reference Si39 504 272 Appendix FXCQ40M 50M 80M 125MVE 3D039557A...

Страница 284: ...Si39 504 Wiring Diagrams for Reference Appendix 273 FXFQ25M 32M 40M 50M 63M 80M 100M 125MVE 3D039600A...

Страница 285: ...Wiring Diagrams for Reference Si39 504 274 Appendix FXKQ25M 32M 40M 63MVE 3D039564B...

Страница 286: ...Si39 504 Wiring Diagrams for Reference Appendix 275 FXDQ20N 25N 32N 40N 50N 63NVE with Drain Pump 3D045500C...

Страница 287: ...Wiring Diagrams for Reference Si39 504 276 Appendix FXDQ20N 25N 32N 40N 50N 63NVET without Drain Pump 3D049604A...

Страница 288: ...Si39 504 Wiring Diagrams for Reference Appendix 277 FXSQ20M 25M 32M 40M 50M 63M 80M 100M 125MVE 3D039561A...

Страница 289: ...Wiring Diagrams for Reference Si39 504 278 Appendix FXMQ40M 50M 63M 80M 100M 125MVE 3D039620B...

Страница 290: ...Si39 504 Wiring Diagrams for Reference Appendix 279 FXMQ200M 250MVE 3D039621B...

Страница 291: ...Wiring Diagrams for Reference Si39 504 280 Appendix FXHQ32M 63M 100MVE 3D039801D...

Страница 292: ...Si39 504 Wiring Diagrams for Reference Appendix 281 FXAQ20M 25M 32MVE 40M 50M 63MVE 3D034206C...

Страница 309: ...Selection of Pipe Size Joints and Header Si39 504 298 Appendix Note 1...

Страница 315: ...Method of Replacing The Inverter s Power Transistors and Diode Modules Si39 504 304 Appendix...