12 Operation

Installation and operation manual

26

RKXYQ5T7Y1B

VRV IV compressor unit for indoor installation

4P408443-1 – 2015.07

Specification

RDXYQ5

Outside ambient

design temperature

Heating

–20~15.5°C WB

Cooling

–5~46°C DB

Ambient design temperature of compressor

unit and heat exchanger unit

5~35°C DB

(26°C WB)

Indoor humidity

≤80%

(a)

(a)

To avoid condensation and water dripping out of the unit. If

the temperature or the humidity is beyond these conditions,

safety devices may be put in action and the air conditioner

may not operate.

Special operation ranges are valid in case of using AHU. They can

be found in the installation/operation manual of the dedicated unit.

Latest information can be found in the technical engineering data.

12.2

Operating the system

12.2.1

About operating the system

▪ Operation procedure varies according to the combination of

compressor unit, heat exchanger unit, and user interface.

▪ To protect the unit, turn on the main power switch 6 hours before

operation.

▪ If the main power supply is turned off during operation, operation

will restart automatically after the power turns back on again.

▪ When stopping the unit, the unit might still operate for a few

minutes. This is not a malfunction.

12.2.2

About cooling, heating, fan only, and

automatic operation

▪ Changeover cannot be made with a user interface whose display

shows

"change-over under centralised control" (refer to

installation and operation manual of the user interface).

▪ When the display

"change-over under centralised control"

flashes, refer to

"12.5.1 About setting the master user

.

▪ The fan may keep on running for about 1 minute after the heating

operation stops.

▪ The air flow rate may adjust itself depending on the room

temperature or the fan may stop immediately. This is not a

malfunction.

12.2.3

About the heating operation

It may take longer to reach the set temperature for general heating

operation than for cooling operation.

The following operation is performed in order to prevent the heating

capacity from dropping or cold air from blowing.

Defrost operation

In heating operation, freezing of the heat exchanger unit's air cooled

coil increases over time, restricting the energy transfer to the heat

exchanger unit's coil. Heating capability decreases and the system

needs to go into defrost operation to be able to deliver enough heat

to the indoor units:

The indoor unit will stop fan operation, the refrigerant cycle will

reverse and energy from inside the building will be used to defrost

the heat exchanger unit coil.

The indoor unit will indicate defrost operation on the displays

.

During defrost operation, ice melts and possibly evaporates.

Possible consequence:

Mist might be visible during or directly after

defrost operation. This is not a malfunction.

Hot start

In order to prevent cold air from blowing out of an indoor unit at the

start of heating operation, the indoor fan is automatically stopped.

The display of the user interface shows

. It may take some

time before the fan starts. This is not a malfunction.

12.2.4

To operate the system (WITHOUT cool/

heat changeover remote control switch)

1

Press the operation mode selector button on the user interface

several times and select the operation mode of your choice.

Cooling operation

Heating operation

Fan only operation

2

Press the ON/OFF button on the user interface.

Result:

The operation lamp lights up and the system starts

operating.

12.2.5

To operate the system (WITH cool/heat

changeover remote control switch)

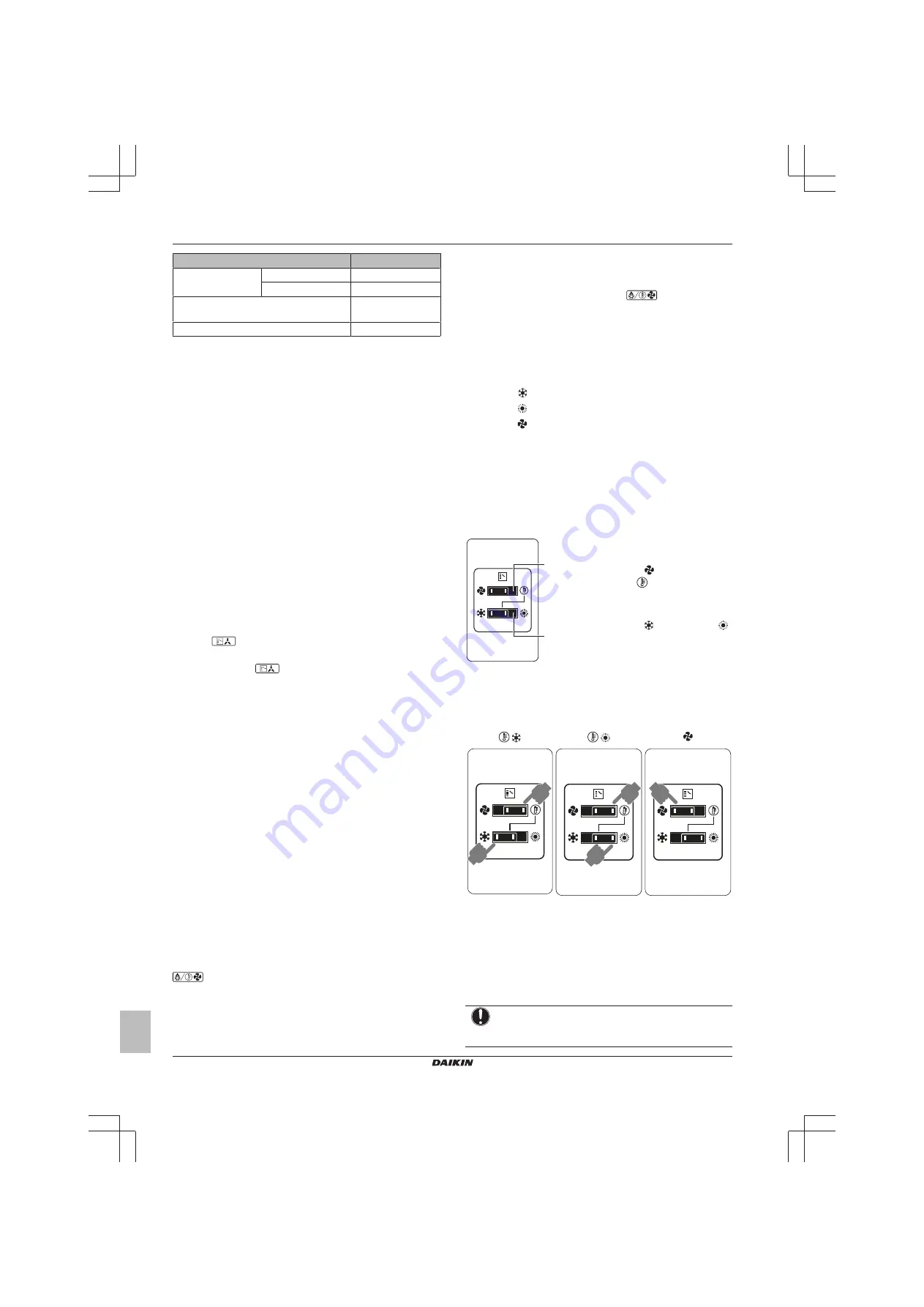

Overview of the changeover remote control switch

a

b

a

FAN ONLY/AIR CONDITIONING

SELECTOR SWITCH

Set the switch to

for fan only

operation or to

for heating or

cooling operation.

b

COOL/HEAT CHANGEOVER SWITCH

Set the switch to

for cooling or to

for heating

To start

1

Select operation mode with the cool/heat changeover switch as

follows:

Cooling operation

Heating operation

Fan only operation

1

1

1

1

1

2

Press the ON/OFF button on the user interface.

Result:

The operation lamp lights up and the system starts

operating.

To stop

3

Press the ON/OFF button on the user interface once again.

Result:

The operation lamp goes out and the system stops

operating.

NOTICE

Do not turn off power immediately after the unit stops, but

wait for at least 5 minutes.