10 About the system

Installation and operation manual

25

RKXYQ5T7Y1B

VRV IV compressor unit for indoor installation

4P408443-1 – 2015.07

1

Several wiring possibilities

Option

Not mounted in switch box

Wiring depending on model

PCB

Legend for wiring diagram RKXYQ5:

A1P

Printed circuit board (main)

A2P

Printed circuit board (inverter)

BS*

Push button (A1P)

C*

Capacitor (A2P)

DS1

DIP switch (A1P)

F1U, F2U

Fuse (T 31.5 A / 250 V) (A1P)

F3U, F5U

Fuse (T 6.3 A / 250 V) (A1P)

H*P

LED (service monitor orange) (A1P)

HAP

Running LED (service monitor green) (A*P)

K1M

Magnetic contactor (A2P)

K1R

Magnetic relay (A*P)

L1R

Reactor

M1C

Motor (compressor)

M1F

Motor (fan)

PS

Switching power supply (A2P)

Q1DI

Earth leakage circuit breaker (field supply)

R*

Resistor (A2P)

R2T

Thermistor (discharge)

R3T

Thermistor (suction accumulator)

R4T

Thermistor (subcool heat exchanger gas)

R5T

Thermistor (suction compressor)

R7T

Thermistor (liquid)

R10T

Thermistor (fin)

S1NPL

Low pressure sensor

S1NPH

High pressure sensor

S1PH

High pressure switch

S*S

Cool/heat selector switch (optional)

V1R

IGBT power module (A2P)

V2R

Diode module (A2P)

X1M

Terminal strip (power supply)

X2M

Terminal strip (transmission wiring)

X*Y

Connector

Y3E

Electronic expansion valve

Y1S

Solenoid valve (4‑way valve)

Z*C

Noise filter (ferrite core)

Z*F

Noise filter (A1P)

For the user

10

About the system

The VRV IV heat pump for indoor installation can be used for

heating/cooling applications.

NOTICE

Do not use the air conditioner for other purposes. In order

to avoid any quality deterioration, do not use the unit for

cooling precision instruments, food, plants, animals or

works of art.

NOTICE

For future modifications or expansions of your system:

A full overview of allowable combinations (for future

system extensions) is available in technical engineering

data and should be consulted. Contact your installer to

receive more information and professional advice.

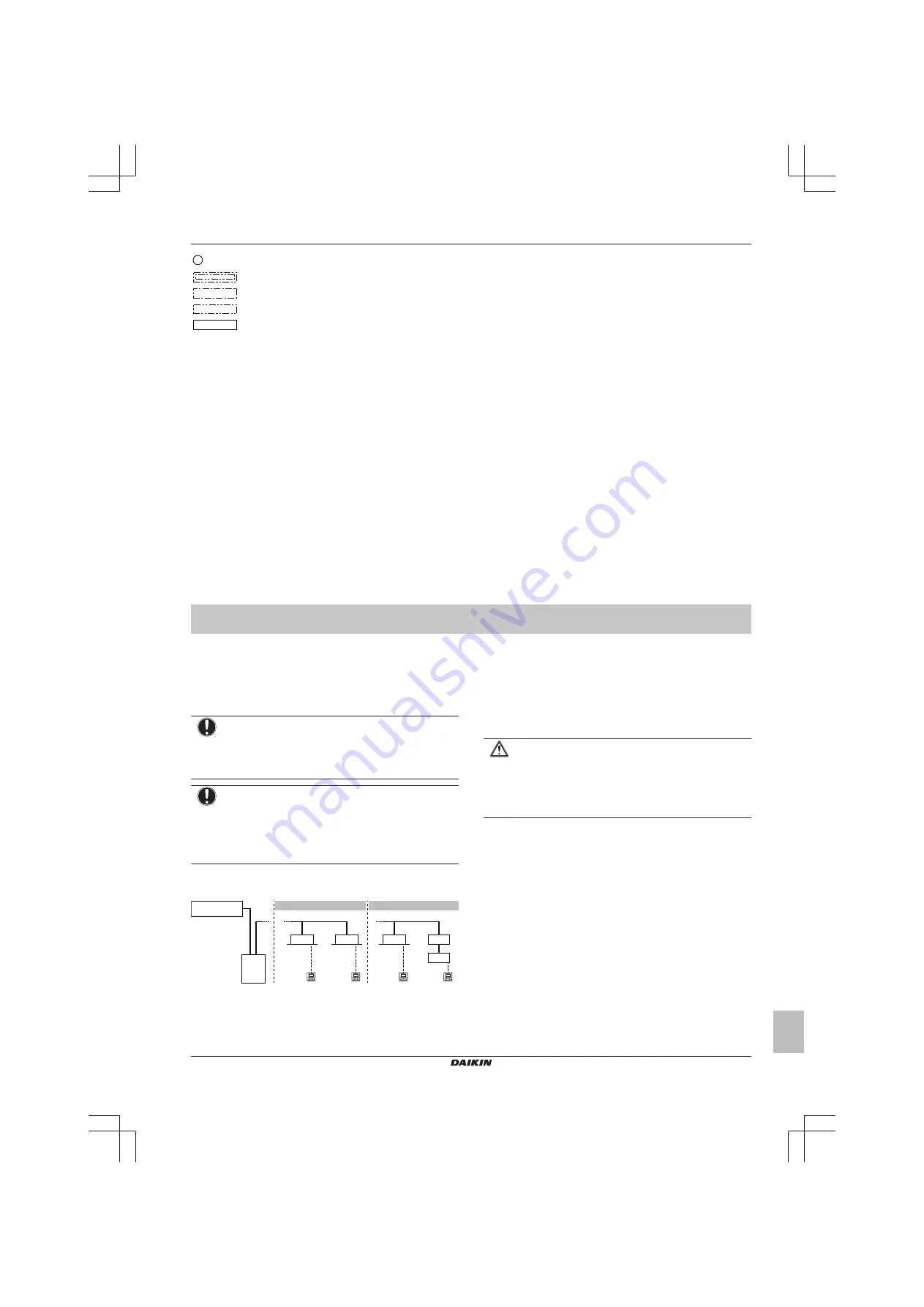

10.1

System layout

d

d

c

c

a

b

VRV DX

VRV DX

VRV DX

EKEXV

AHU

d

d

1

2

1

In case of VRV DX indoor units

2

In case of VRV DX indoor units combined with an air

handling unit

a

Heat exchanger unit

b

Compressor unit

c

Refrigerant piping

d

User interface (dedicated depending on indoor unit type)

VRV DX

VRV direct expansion (DX) indoor unit

EKEXV

Expansion valve kit

AHU

Air handling unit

11

User interface

CAUTION

Never touch the internal parts of the controller.

Do not remove the front panel. Some parts inside are

dangerous to touch and appliance problems may happen.

For checking and adjusting the internal parts, contact your

dealer.

This operation manual will give a non-exhaustive overview of the

main functions of the system.

Detailed information on required actions to achieve certain functions

can be found in the dedicated installation and operation manual of

the indoor unit.

Refer to the operation manual of the installed user interface.

12

Operation

12.1

Operation range

Use the system in the following temperature and humidity ranges for

safe and effective operation.