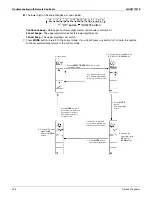

Troubleshooting by Error Code

SiUS371901E

241

Service Diagnosis

E9 - 01

Electronic expansion valve coil (Y1E) error (Master)

Refer to the

E9

flowchart of each manual and make a diagnosis

of the relevant electronic expansion valve of the relevant unit

based on the Error code shown to the left.

E9 - 03

Electronic expansion valve coil (Y2E) error (Master)

E9 - 04

Electronic expansion valve coil (Y3E) error (Master)

E9 - 05

Electronic expansion valve coil (Y1E) error

(Slave 1)

E9 - 06

Electronic expansion valve coil (Y2E) error

(Slave 1)

E9 - 07

Electronic expansion valve coil (Y3E) error

(Slave 1)

E9 - 08

Electronic expansion valve coil (Y1E) error

(Slave 2)

E9 - 09

Electronic expansion valve coil (Y2E) error

(Slave 2)

E9 - 10

Electronic expansion valve coil (Y3E) error

(Slave 2)

E9 - 20

Defective electronic expansion valve coil (Y1E)

(Master)

E9 - 21

Defective electronic expansion valve coil (Y1E)

(Slave 1)

E9 - 22

Defective electronic expansion valve coil (Y1E)

(Slave 2)

E9 - 23

Defective electronic expansion valve coil (Y2E)

(Master)

E9 - 24

Defective electronic expansion valve coil (Y2E)

(Slave 1)

E9 - 25

Defective electronic expansion valve coil (Y2E)

(Slave 2)

E9 - 26

Electronic expansion valve coil (Y4E) error

(Master)

E9 - 27

Electronic expansion valve coil (Y4E) error

(Slave 1)

E9 - 28

Electronic expansion valve coil (Y4E) error

(Slave 2)

E9 - 29

Electronic expansion valve coil (Y5E) error

(Master)

E9 - 32

Electronic expansion valve coil (Y7E) error

(Master)

E9 - 34

Electronic expansion valve coil (Y5E) error

(Slave 1)

E9 - 37

Electronic expansion valve coil (Y7E) error

(Slave 1)

E9 - 39

Electronic expansion valve coil (Y5E) error

(Slave 2)

E9 - 42

Electronic expansion valve coil (Y7E) error

(Slave 2)

E9 - 44

Defective electronic expansion valve coil (Y3E)

(Master)

E9 - 45

Defective electronic expansion valve coil (Y3E)

(Slave 1)

E9 - 46

Defective electronic expansion valve coil (Y3E)

(Slave 2)

Error code

Troubleshooting

Error description

Diagnosis

Содержание REYQ-XA

Страница 1: ...Service Manual SiUS371901E REYQ72 456XATJU REYQ72 456XAYDU REYQ72 432XAYCU Heat Recovery 60 Hz...

Страница 414: ...Wiring Diagrams SiUS371901E 401 Appendix 1 Wiring Diagrams 1 1 Outdoor Unit REYQ72 96 120XATJU 2D119205A...

Страница 415: ...SiUS371901E Wiring Diagrams Appendix 402 REYQ144 168XATJU 2D119206A...

Страница 416: ...Wiring Diagrams SiUS371901E 403 Appendix REYQ72 96 120XAYDU 2D119207B...

Страница 417: ...SiUS371901E Wiring Diagrams Appendix 404 REYQ144 168XAYDU 2D119208B...

Страница 418: ...Wiring Diagrams SiUS371901E 405 Appendix REYQ72 96 120 144 168XAYCU 2D119209A...

Страница 419: ...SiUS371901E Wiring Diagrams Appendix 406 1 2 Indoor Unit FXFQ07 09 12 15 18 24 30 36 48TVJU 3D086460B...

Страница 420: ...Wiring Diagrams SiUS371901E 407 Appendix BYCQ125BGW1 Self Cleaning Decoration Panel for FXFQ TVJU 3D076375A...

Страница 421: ...SiUS371901E Wiring Diagrams Appendix 408 FXZQ05 07 09 12 15 18TAVJU 3D110443A...

Страница 423: ...SiUS371901E Wiring Diagrams Appendix 410 FXEQ07 09 12 15 18 24PVJU 3D098557A...

Страница 425: ...SiUS371901E Wiring Diagrams Appendix 412 FXSQ05 07 09 12 15 18 24 30 36 48 54TAVJU C 3D110467C...

Страница 426: ...Wiring Diagrams SiUS371901E 413 Appendix FXMQ07 09 12 15 18 24 30 36 48 54PBVJU 3D093209B...

Страница 428: ...Wiring Diagrams SiUS371901E 415 Appendix FXHQ12 24 36MVJU 3D048116C...

Страница 429: ...SiUS371901E Wiring Diagrams Appendix 416 FXAQ07 09 12 18 24PVJU C 3D075354D...

Страница 434: ...Wiring Diagrams SiUS371901E 421 Appendix 1 3 2 Energy Recovery Ventilator VAM Series VAM300 470 600GVJU 3D073269D...

Страница 435: ...SiUS371901E Wiring Diagrams Appendix 422 VAM1200GVJU 3D073270D...

Страница 437: ...SiUS371901E Wiring Diagrams Appendix 424 1 4 2 Multi Branch Selector Unit BS4Q54TVJ 3D089123B...

Страница 438: ...Wiring Diagrams SiUS371901E 425 Appendix BS6 8Q54TVJ 2D089122B...

Страница 439: ...SiUS371901E Wiring Diagrams Appendix 426 BS10 12Q54TVJ 2D089121B...

Страница 440: ...Revision History Month Year Version Revised contents 04 2019 SiUS371901E First edition...