EDUS39-900-F10

Installation

FXMQ-MF

23

Refri

g

erant Pipin

g

Work

<For refri

g

erant pipin

g

between outdoor unit and this unit, see the installation manual attached to the outdoor

unit. (Refer to Table 1)>

<Execute heat insulation work completely on both sides of the

g

as pipe and the liquid pipe. Otherwise, a water

leaka

g

e can result sometimes.>

<Be sure to use insulation that is desi

g

ned for use with HVAC Systems.>

<Improve the insulation on the refri

g

erant pipin

g

dependin

g

on the installation environment. If the insulation is

not sufficient, condensate may form on the surface of the insulation.>

<Before refri

g

erant pipin

g

work, check which type of refri

g

erant is used. Proper operation is not possible if the

types of refri

g

erant are not the same.>

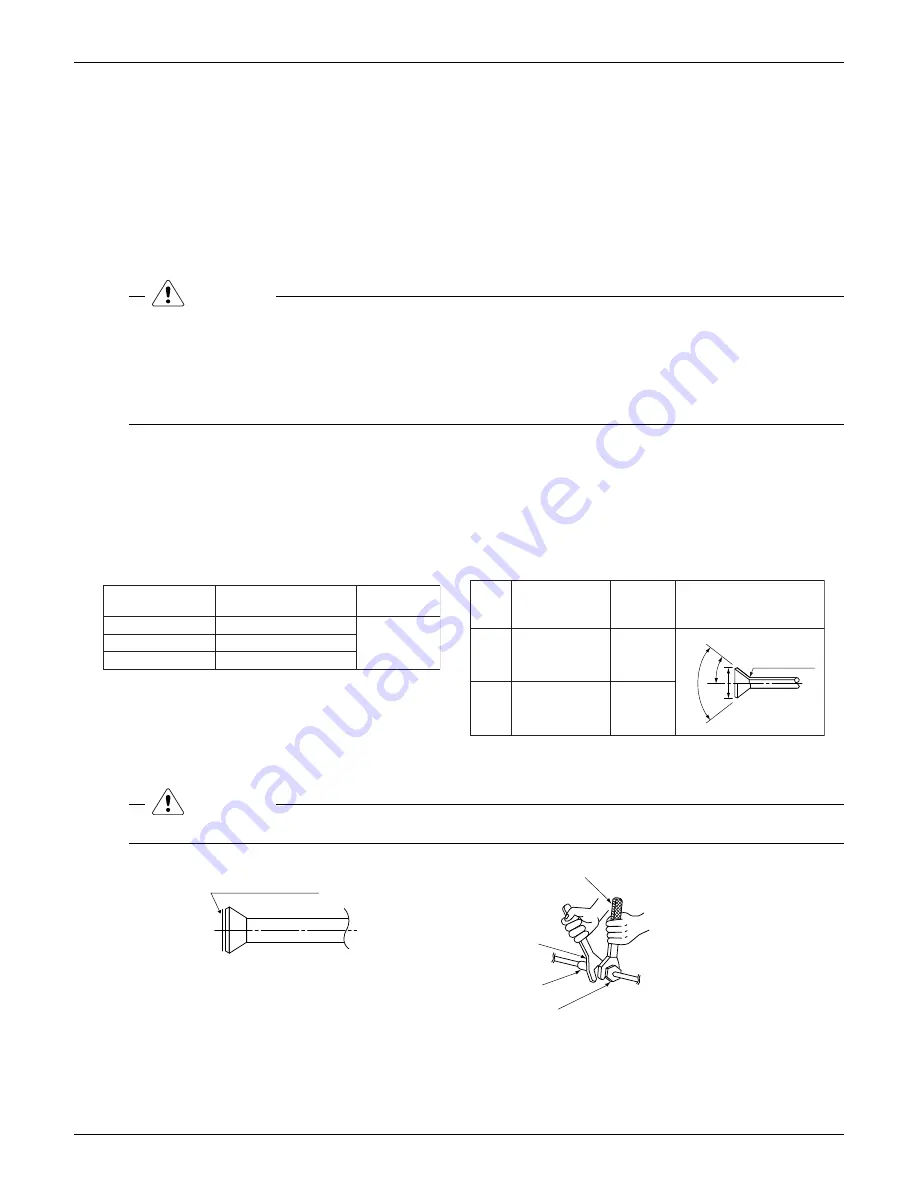

CAUTION

Use a pipe cutter and flare suitable for the type of refri

g

erant.

Apply ester oil or ether oil inside the flare portions before connectin

g

. (Refer to Fi

g

. 7)

To prevent dust, moisture or other forei

g

n matter from infiltratin

g

the tube, either pinch the end or cover it

with tape.

Do not allow anythin

g

other than the desi

g

nated refri

g

erant to

g

et mixed into the refri

g

erant circuit, such as

ir, etc. If any refri

g

erant

g

as leaks while workin

g

on the unit, ventilate the room thorou

g

hly ri

g

ht away.

TThe outdoor unit is charged

w

ith refrigerant.

Be sure to use both a spanner and torque

w

rench together, as sho

w

n in the dra

w

ing,

w

hen connecting or

disconnecting pipes to/from the unit.

(Refer to Fi

g

. 8)

Refer to Table 2 for the dimensions of flare nut spaces.

When connecting the flare nut, coat the flare section inside

w

ith ester oil or ether oil, rotate three or four times first,

then scre

w

in.

(Refer to Fi

g

. 7)

Refer to Table 2 for tightening torque.

Note:

Use the flare nuts attached

w

ith the unit.

CAUTION

Over-tightening may damage the flare and cause a refrigerant leakage.

Table 1

Unit to be connected

Gas pipe diameter

Liquid pipe

diameter

φ

5/8

φ

3/8

φ

3/4 Use attached pipe.

FXMQ48MF

V

JU

FXMQ72MF

V

JU

FXMQ96MF

V

JU

φ

7/8 Use attached pipe.

Table 2

Pipe

size

Tightening torque

(ft·lbf)

Flare shape (in.)

φ

3/8”

24.1 – 29.4

0.504 – 0.520

φ

5/8”

45.6 – 55.6

0.760 – 0.776

Flare dimen-

sions

A (in.)

A

45

0

±2

0

90

0

±2

0

R0.016-0.031

Ester oil or ether oil.

Fi

g

. 7

Torque

w

rench

Spanner

Piping union

Flare nut

Fi

g

. 8

Содержание FXMQ-MF

Страница 1: ...EDUS 39 900 F10_a AMERICAS FXMQ MF Outdoor Air Processing Unit ...

Страница 6: ...EDUS39 900 F10 Dimensions FXMQ MF 5 3 Dimensions 3 1 Indoor Units FXMQ48MFVJU Unit in 3D065452A ...

Страница 7: ...Dimensions EDUS39 900 F10 6 FXMQ MF FXMQ72MFVJU FXMQ96MFVJU Unit in 3D065453A ...

Страница 8: ...EDUS39 900 F10 Piping Diagrams FXMQ MF 7 4 Piping Diagrams 4D018650C ...

Страница 16: ...EDUS39 900 F10 Fan Performances FXMQ MF 15 9 Fan Performances FXMQ48MFVJU FXMQ72MFVJU 3D065649B 3D065650B ...

Страница 17: ...Fan Performances EDUS39 900 F10 16 FXMQ MF FXMQ96MFVJU 3D065651B ...

Страница 19: ...Sound Levels Reference EDUS39 900 F10 18 FXMQ MF FXMQ96MFVJU 4D068577 ...