4 Installation

Installation manual

13

D035A1/4AA + D035A4AA

Wall-mounted condensing boiler

3P469346-5E – 2017.06

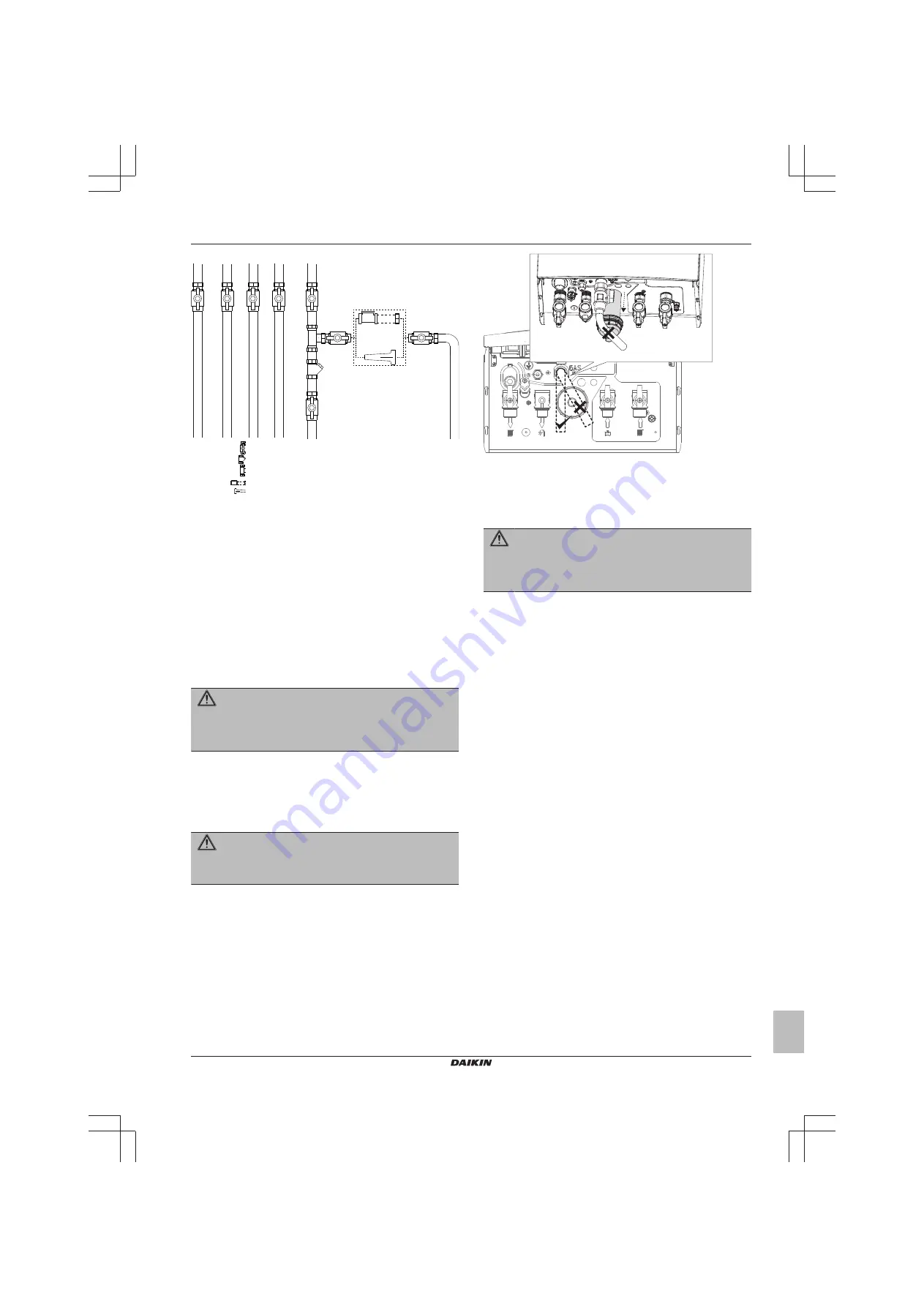

A

a

B

F

D

E

Valve

Strainer

Tee connection

Double check valve + filling hose

Disconnector

a

External filling group used with models D2TND028A4AA

and D2TND035A4AA. Use a disconnector or a double

check valve according to local regulations.

Isolation valves and strainers should be used just before the

appliance piping inlet as shown in figure above. Boiler is filled with

external fresh water supply.

Ensure that necessary gaskets are placed.

Note:

Optional Daikin connection kit can be used and it is

recommended to use it.

4.8.2

Guidelines when connecting the gas

piping

This unit is designed to be operated with natural gas or LPG. The

preset gas type and the designated gas inlet pressure are indicated

on the boiler's identification label.

WARNING

Only qualified persons are allowed to connect the gas

piping. The gas inlet pipe diameter must be selected

according to the applicable legislation, standards, and

regulations.

Connect the gas piping according to applicable legislation of the

country of destination and the regulations of the gas supply

company.

Connect the gas supply piping without tension to the gas pipe

connection ("Connection F", see

WARNING

After the gas connection is made, the gas line must be

tested for leakage while the gas line to the boiler is open

(see

"5.3 To check for gas leakage" on page 26

In case gas piping is adjacent to the wall and is to be connected to

the gas pipe connection of the boiler with an elbow, enough space

for taking out the condensate trap must be left. This can be done in

two ways:

1

Elbow must be placed crosswise so it will not block the

condensate trap when it is being taken out.

2

Elbow must be placed 200 mm below the gas piping connection

of the boiler.

4.8.3

Guidelines when connecting the water

piping

When connecting the piping to the boiler, observe the following

instructions:

WARNING

Ignoring the rules explained below may result in serious

damages in installation or boiler or cause discomfort of the

user. The manufacturer is not responsible for any damage

that may occur this way.

▪ The installation of the boiler should be in compliance with the

applicable legislation, standards, and regulations.

▪ The materials used in the installation must be in compliance with

the applicable legislation, standards, and regulations.

▪ Heating installation piping material must not allow oxygen diffusion

according to DIN4726.

▪ The central heating/domestic hot water installation should be

flushed and visually inspected. Wastes, dust, rubbers, and metal

pieces generated during the installation and mounting of the boiler

must be removed in order not to cause any damage.

▪ The central heating circuit must be able to withstand a pressure of

at least 6 bar.

▪ Cross connection must be preferred in the radiators longer than

1.5 metres.

▪ The safety valve piping should be connected to a water outlet with

an additional hose or piping. This outlet should not be installed in

places where there is risk of freezing, nor in the rain gutter, it

should not end to dry floor without available drainage to avoid

damaging of floor coating like parquet.

▪ The maximum pressure in the domestic hot water circuit is 10 bar.

Inspect the piping taking this in to consideration. If the water

pressure of the main water supply is excessive, use an

appropriate pressure reducer. Installation must comply with

EN 15502-2-2.

▪ As the condensing boilers generate condensate, the condensate

trap outlet should be connected to an open drain. Piping and

elements of the drain line must be made of acid-resistant material

like plastics. Metals like steel or copper are not allowed.

▪ The system must be air-free to protect the boiler. There are two

automatic air vents on the boiler, one at heat exchanger, the other

on the pump. Ensure air is discharged completely at each water

filling. Bleed the radiators if necessary.

▪ If the boiler will be connected to an old central heating/domestic

hot water installation, then first visually inspect the old installation.

The installation must be in compliance with the capacity of the

boiler and must not prevent the efficient running of it. Dirt in old

system and piping must be flushed, and filters must be inspected.