4 Installation

Installation manual

12

D035A1/4AA + D035A4AA

Wall-mounted condensing boiler

3P469346-5E – 2017.06

4.6

Underfloor heating requirements

Underfloor heating systems apparently require higher flow rate and

lower ΔT. This boiler can be connected to an underfloor heating

system without use of a second pump and low loss header because

of its high pump capacity. Direct connection is possible when the

system is well designed and pressure loss is low enough.

When the boiler is connected to underfloor heating installation, the

maximum central heating set temperature must be limited to 50°C

and the pump operation temperature difference must be adjusted to

10 Kelvin in the service settings menu. To change this setting, refer

to the servicing instructions.

WARNING

Make sure parameter changes explained above are done

to avoid discomfort of the user.

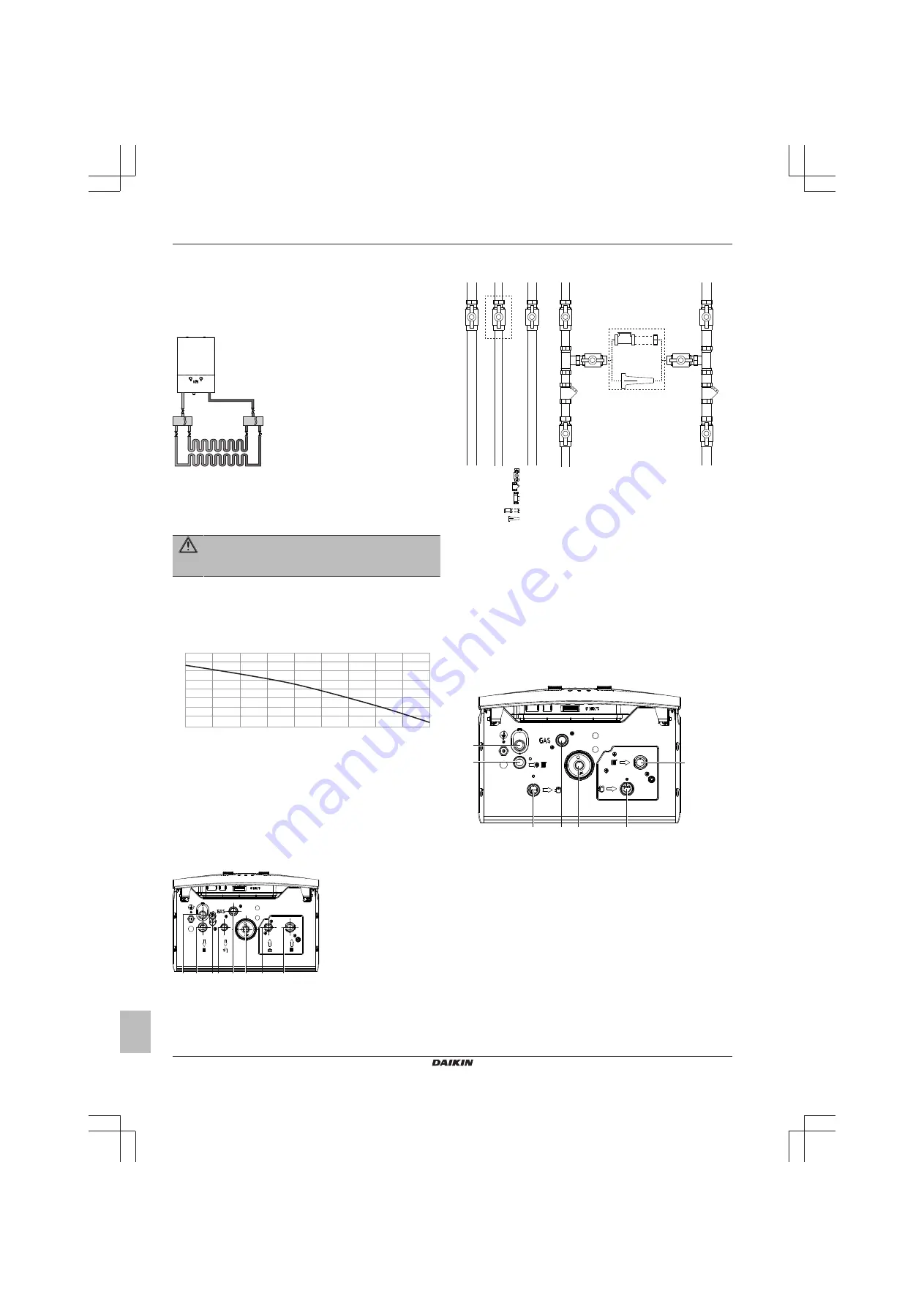

4.7

Residual pump lift graph

The residual pump lift graph shows the amount of pump lift (mbar)

that remains for the central heating circuit.

0

0

100

200

300

400

500

600

700

800

200

400

600

800

1000

1200

1400

1600

1800

A (mbar)

B (l/h)

A

Residual pump lift (mbar)

B

Flow (l/h)

4.8

Connections

4.8.1

Piping connections

Piping connections of models D2CND028A1AA,

D2CND028A4AA, D2CND035A1AA and D2CND035A4AA

Below, find the piping connections of the unit.

A

B

D

E

H

C

F

G

A

Central heating return connection, 3/4"

B

Domestic cold water inlet connection, 1/2"

C

Condensate trap discharge

D

Domestic hot water outlet connection, 1/2"

E

Central heating supply connection, 3/4"

F

Gas inlet connection, 3/4"

G

Filling valve (for D2CND028A1AA and D2CND035A1AA)

H

Safety valve discharge

B

F

D

a

b

E

A

Valve

Strainer

Tee connection

Double check valve + filling hose

Disconnector

a

Isolation valve on domestic hot water supply pipe is

tentative.

b

External filling group used with model D2CND028A4AA

and D2CND035A4AA. Use a disconnector or a double

check valve according to local regulations.

Isolation valves and strainers should be used just before the

appliance piping inlet as shown in figure above.

Ensure that necessary gaskets are placed.

Note:

Optional Daikin connection kit can be used and it is

recommended to use it.

Piping connections of models D2TND028A4AA and

D2TND035A4AA

Below, find the piping connections of the unit.

B

D

C

A

E

G

F

A

Central heating return connection, 3/4"

B

Storage tank return connection, 3/4"

C

Condensate trap discharge

D

Storage tank supply connection, 3/4"

E

Central heating supply connection, 3/4"

F

Gas inlet connection, 3/4"

G

Safety valve discharge