IM 817-4

Page 31 of 60

Checking System Charge

The system charge should be checked under design conditions [95ºF

outside air, 80ºF/67ºF (DB/WB) indoor air]. Refer to condensing unit

manufacturer's guidelines.

Before adjusting refrigerant charge, verify that the unit ventilator is

operating at normal design cfm. Nominal cfm is determined with a dry

coil, and cfm will be reduced during air conditioning operation with a

wet coil. Filters and coil must be clean and fan speed set at high.

temperature to obtain subcooling.

Typical conditions - 95

º

F ambient, 75 psig suction, 285 psig head

pressure, 6-7

º

F superheat, 15

º

F subcooling.

Liquid

Line

Drier

Hazardous Voltage!

Disconnect all electric power including remote disconnects

before servicing. Failure to disconnect power before servicing

can cause severe personal injury or death.

Sight Glass

TXV (Thermal Expansion Valve)

Insulate Bulb, (Reacts

To Refrigerant Tempera

-

ture and Not Ambient)

Insulate The Suction

Line Piping, (Minimum

Heat Pickup)

Return (Suction Line)

Supply (Liquid Line)

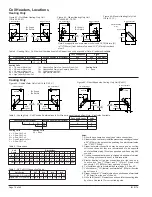

Figure 88 - Insulate Bulb and Suction Line Piping

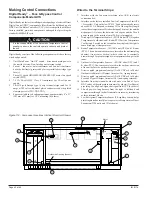

Figure 89 - Typical Split System Evacuation/Charging Setup

Suction Line Service Valve

Liquid Line Service Valve

Outdoor Fan

Compressor

Gauge Bar Hoses

Vacuum Pump

TXV

Indoor Fans

Charging

Cylinder

Indoor Coil

Outdoor Coil

Low Pressure

Gauge

Outdoor Condensing Unit

Unit Ventilator

High Pressure

Gauge

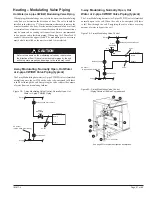

Figure 90 - Typical Unit Ventilator/Condensing Unit Wiring Diagram

Compressor

Compressor

Contactor

Capacitor

Head

Pressure

Controller

(Optional)

Fan

Motor

High

Pressure

Switch

Low

Pressure

Switch

TDR = Time Delay Relay

TB = Terminal Block

T4

2

3

1

Rec3

Line

Vo

ltage

Factory Wired

Field Wired (By Others)

TDR or TB

Low Ambient

T

emp. Switch

To controls by others, to energize condensing unit normally

open contact.

T

1

T

2

L

2

L

1

L

2

L

1

24V

24V

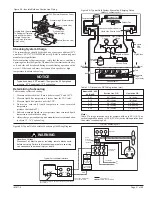

Determining Subcooling

To determine correct subcooling:

1. Measure outdoor ambient. It must be between 65ºF and 105ºF.

2. Measure liquid line temperature 6 inches from the TXV inlet.

3. Measure liquid line pressure near the TXV.

4. Determine saturated liquid temperature from saturated

temperature

pressure chart (table 22).

5. Subtract measured liquid line temperature from saturated liquid

temperature to obtain subcooling.

6. Adjust charge per condensing unit manufacturer recommendation

to obtain 15 - 16ºF subcooling.

(By Others)

(By Others)

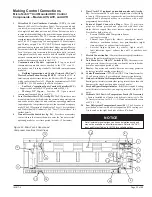

Note:

Table 21 piping dimensions are for systems with up to 30 ft. (9.14 m)

vertical separation and up to 100 ft

(30.47 m) horizontal separation from

the outdoor condensing unit.

Table 21 - Dimensions, DX Tubing inches (mm)

Models AVS, AVV,

AVB, AVR

Suction Line O.D.

Liquid Line O.D.

S07

3/4" (19mm)

1/4" (6mm)

S10

3/4" (19mm)

1/4" (6mm)

S13

7/8" (22mm)

3/8" (10mm)

S15

7/8" (22mm)

3/8" (10mm)

S20

7/8" (22mm)

3/8" (10mm)

Typical Condensing Unit

Typical Unit Ventilator Interface

Pressure

Taps

(by others)

Pressure Taps (Field Installed)

Pressure Taps

(Field Installed)

NOTICE

WARNING