IM 817-4

Page 27 of 60

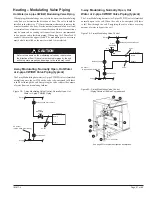

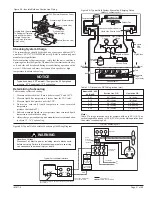

Heating – Modulating Valve Piping

Hot Water (or 2-pipe CW/HW) Modulating Valve Piping

Return

Return

Balancing and Shutoff Valve

Shutoff Valve

Supply

Supply

2-way

Modulating

Valve

Unit Coil

Unions

2-way Modulating, Normally Open, Hot Water

or 2-pipe CW/HW Valve Piping (typical)

The 2-way Modulating hot water (or 2-pipe CW/HW) valve is furnished

normally open to the coil. When the valve is de-energized (off) there

is full flow through the coil. Energizing the valve reduces the volume

of water flow in a modulating fashion.

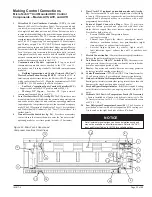

3-way Modulating, Normally Open, Hot

Water or 2-pipe CW/HW Valve Piping (typical)

The 3-way Modulating hot water (or 2-pipe CW/HW) valve is furnished

normally open to the coil. When the valve is de-energized (off) there

is full flow through the coil. Energizing the valve allows a varying

amount of water to bypass the coil.

Return

Return

Balancing and Shutoff Valve

Shutoff Valve

Supply

Supply

3-way

Modulating

Valve

Unit Coil

Union

Union

Balancing Valve

N.O.

Common

N.C.

When piping the modulating valve, refer to the arrows on the modulating

valve body to determine the direction of flow. The valve should be

installed so that there is a 2" (51mm) minimum clearance to remove the

actuator form the valve body. Provide unions for removal of unit coil and/

or control valve as a future service consideration. Hot water connections

may be same end as cooling coil connections, but are recommended

to be opposite end to facilitate piping. When using AAF MicroTech II

controls, they must be opposite end. The modulating valve accessory

must be field installed on the unit for which it was selected.

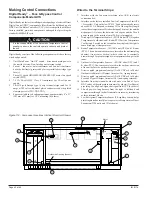

S5 Sensor

(2-pipe CW/HW Units Only)

S5 Sensor

(2-pipe CW/HW Units Only)

Figure 80 - 3-way Modulating Valve Control

(Piping Outside Unit End Compartment)

2

3

4

5

6

7

15

15

15

11

S5 Sensor

Refer to the arrows on the modulating valve body to determine

the direction of flow. If the valve is mounted improperly, the unit

will not operate properly and damage to the valve may result.

See page 25 for number designation descriptions.

Figure 78 - 2-way Modulating Valve Control, Normally Open, Hot

Water or 2-pipe CW/HW Piping

Figure 79 - 3-way Modulating Valve Control

CAUTION