4 Installation

Installation manual

13

EABH/9W

Daikin Altherma 3 H W

4P644479-1 – 2020.12

X5M

A4P

X1M

YC Y1

YC Y2

Y2 Y3 Y4

X2M

X1M

7 9

a

a

Installation of EKRP1HBAA is required.

2

Fix the cable with cable ties to the cable tie mountings.

4.4.10

To connect the changeover to external

heat source

1

Connect the changeover to external heat source cable to the

appropriate terminals as shown in the illustration below.

X5M

A4P

X1M

YC Y1 Y2 Y3 Y4

X2M

X1M

X3

X4

X2M

X1

X2

L N

a

a

Installation of EKRP1HBAA is required.

2

Fix the cable with cable ties to the cable tie mountings.

4.4.11

To connect the power consumption digital

inputs

1

Connect the power consumption digital inputs cable to the

appropriate terminals as shown in the illustration below.

X5M

A8P

1 2 3 4 5

X801M

S6S

S7S

S8S

S9S

a

a

Installation of EKRP1AHTA is required.

2

Fix the cable with cable ties to the cable tie mountings.

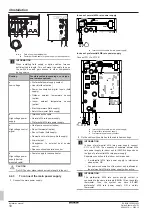

4.4.12

To connect the safety thermostat

(normally closed contact)

1

Connect the safety thermostat (normally closed) cable to the

appropriate terminals as shown in the illustration below.

X5M

910

2

Fix the cable with cable ties to the cable tie mountings.

NOTICE

Make sure to select and install the safety thermostat

according to the applicable legislation.

In any case, to prevent unnecessary tripping of the safety

thermostat, we recommend the following:

▪ The safety thermostat is automatically resettable.

▪ The safety thermostat has a maximum temperature

variation rate of 2°C/min.

▪ There is a minimum distance of 2 m between the safety

thermostat and the motorized 3‑way valve delivered

with the domestic hot water tank.

INFORMATION

ALWAYS configure the safety thermostat after it is

installed. Without configuration, the unit will ignore the

safety thermostat contact.

INFORMATION

The preferential kWh rate power supply contact is

connected to the same terminals (X5M/9+10) as the safety

thermostat. Thus, the system can have EITHER

preferential kWh rate power supply OR a safety

thermostat.

4.5

Finishing the indoor unit

installation

4.5.1

To close the indoor unit

1

Reinstall the user interface panel.

2

Reinstall the switch box cover and close the switch box.

3

Reinstall the front panel.

Содержание Altherma 3 H W

Страница 29: ......

Страница 30: ......

Страница 31: ......

Страница 32: ...4P644479 1 2020 12 Copyright 2018 Daikin 4P644479 1 0000000W Verantwortung f r Energie und Umwelt...