43

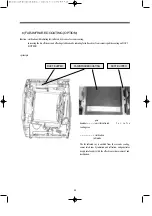

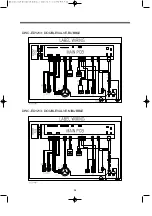

6) FAR-INFRARED COATING (OPTION)

function : steilization with radiating far- infra red, by means of ceremic coating.

increasing the dry efficiency and effecting sterilization by radiating far infra-red ray from ceramic particle coating on DUCT

B UPPER

• principle

DUCT B UPPER

FAR-INFRARED COATING

DUCT B UPPER

heated air ---------> emit far-infra red

f a r - i n f r a

coating area

---------------------> steilization

The far infrared ray is emitted from the ceramic coating,

comes into drum by radiation and reflection, and penetrates

deeply into laundry with the effective moisture removal and

sterilization.

pass

tub inside

Содержание DWC-ED1213

Страница 10: ...7 3 VERIFICATIONOFDRUM ASSY...

Страница 11: ...7...

Страница 16: ...12 3 CABINETFAS...

Страница 19: ...15 5 DUCT DUCTPIPEAS...

Страница 21: ...17 6 CABINETAS...

Страница 23: ...19 7 BASEUAS...

Страница 25: ...21 8 TUBAS...

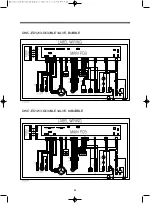

Страница 51: ...47 DWC ED1213 DOUBLE VALVE BUBBLE DWC ED1213 DOUBLE VALVE N BUBBLE 7 Wiring Diagram...

Страница 52: ...48 DWC ED1213 DOUBLE VALVE BUBBLE DWC ED1213 DOUBLE VALVE N BUBBLE...

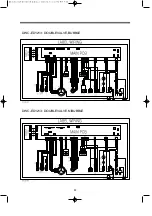

Страница 53: ...49 DWC ED1213 DOUBLE VALVE BUBBLE DWC ED1213 DOUBLE VALVE N BUBBLE...

Страница 54: ...50 DWC ED1213 DOUBLE VALVE BUBBLE DWC ED1213 DOUBLE VALVE N BUBBLE...

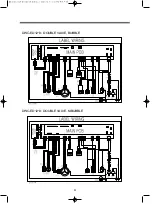

Страница 55: ...51 DWC ED1213 DOUBLE VALVE BUBBLE DWC ED1213 DOUBLE VALVE N BUBBLE...

Страница 56: ...52 DWC E1213 DOUBLE VALVE BUBBLE DWC E1213 DOUBLE VALVE N BUBBLE...

Страница 57: ...53 DWC ED1213 DOUBLE VALVE BUBBLE DWC ED1213 DOUBLE VALVE N BUBBLE...

Страница 58: ...54 DWC ED1213 DOUBLE VALVE BUBBLE DWC ED1213 DOUBLE VALVE N BUBBLE...

Страница 63: ...2005 09 DRUM WASHING MACHINE 686 360 8282 http www dwe daewoo co kr...

Страница 64: ...SVCMANUAL DWD E1200R S DWD E1200W S 2005 09 DRUM WASHING MACHINE DRUMWASHINGMACHINE...