Power Input:

110~250 Volts AC 50/60Hz

¡

120 Volts AC 60Hz

¡¡

Power Consumption:

17 Watts (2-head and 4-head)

Operating Temperature:

5 degree C to 40 degree C

(41 degree F to 104 degree F)

Storage Temperature:

-30 degree C to 65 degree C

(-22 degree F to 149 degree F)

Weight:

3.6 kg

Dimensions:

360mm Wide X 90mm High X

278mm Deep

Recording System:

4-head: Four video record/playback

heads

Rotary helical scan/luma: FM

recording/chroma: converted

subcarrier phase shifted recording

2-head: Two video/playback heads

Rotary helical scan/luma: FM

recording/chroma: converted

subcarrir phase shifted recording

Video head

¡

: K584NY-SJ/M, K584NZ-SJ/M,

K584NZ-SG/M

¡¡

: K584N-SJ, K584N-JJ, K584N-SG,

K484N-SJ, K484N-JJ, K484N-SG,

K384N-SJ, K284N-SJ, K504N-SJ,

K504NY-SG/X, K304N-SJ

Video Signal:

EIA standard; NTSC color

Antenna:

75 ohm input impedance

Video Signal Level:

1Vp-p (140 IRE standard)

Audio Input Impedance:

47k ohms

Audio Output

Impedance:

Less than 1.5k ohm

Tape Speed:

SP: 33.35mm/sec.

SLP: 11.13mm/sec

Maximum Recording Time: T-60: 3 hours/SLP mode

T120: 6 hours/SLP mode

Fast Forward/Rewind Time: 3 minutes (T-120 tape)

Tuning System:

Auto Program/Cable

Compatible/Frequency

Synthesis (FS)

Note: Specifications are subject to change without notice.

1

SPECIFICATIONS

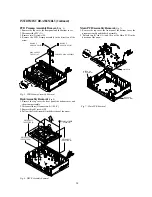

Cleaning and Lubrication

A. Cleaning the Tape Transport System

The following parts should be cleaned after every 500 hours

of use.

• TENSION POLE

• S-GUIDE POST

• FE HEAD

• S GUIDE ROLLER

• S-SLANT POLE

• VIDEO HEAD/DRUM

• T-SLANT POLE

• T-GUIDE ROLLER

• AC HEAD/AE HEAD

• T-GUIDE POST

• CAPSTAN SHAFT

• PINCH ROLLER

Note: After cleaning with alcohol, allow the parts to dry thor-

oughly before using a cassette tape.

B. Cleaning the Drive System

The following parts should be cleaned after every 500 hours

of use.

• REEL TABLE

• T MAIN BRAKE

• S MAIN BRAKE

• T MAIN BRAKE

• CAPSTAN FLYWHEEL/PULLEY

• REEL PULLEY

C. Lubrication points

The following parts should be cleaned and lubricated after

every 500 hours of use. Apply one (1) or two (2) drops of oil.

Refer to the "Replacement Parts List" for the stock number of

the recommended oil.

• S REEL TABLE POST

• T REEL TABLE POST

• IDLER PULLEY

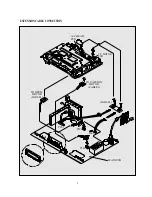

CLEANING AND LUBRICATION

Содержание DV- K504N-SJ

Страница 35: ...34 AC001 K584NZ SJ M K584NZ SG M only...

Страница 36: ...35...

Страница 37: ...36...

Страница 38: ...37...

Страница 39: ...38...

Страница 60: ...59 ELECTRICAL ADJUSTMENTS Fig 1 Circuit Board Location...

Страница 92: ...91 INTERCONNECT WIRING DIAGRAM K584N K484N K384N K284N...

Страница 93: ...92 POWER SUPPLY SCHEMATIC DIAGRAM FREE VOLTAGE K584NY SJ M K584NZ SJ M K584NZ SG M...

Страница 95: ...94 2HD HEAD AMP SCHEMATIC DIAGRAM K384N K284N K304N...

Страница 96: ...95 4HD HEAD AMP SCHEMATIC DIAGRAM K584N K484N K504N...

Страница 97: ...96 VIDEO AUDIO SCHEMATIC DIAGRAM K584N K484N K384N K284N K504N K304N...

Страница 98: ...97 PIF INPUT SELECTOR SCHEMATIC DIAGRAM 9V USE K584NY SJ M K584NZ SJ M K584NZ SG M...

Страница 100: ...99 TIMER SYSCON SCHEMATIC DIAGRAM K584N K484N K384N K284N K504N K304N...

Страница 101: ...100 POWER SUPPLY BLOCK DIAGRAM FREE VOLTAGE K584NY SJ M K584NZ SJ M K584NZ SG M...

Страница 103: ...102 2HD HEAD AMP BLOCK DIAGRAM K384N K284N K304N...

Страница 104: ...103 4HD HEAD AMP BLOCK DIAGRAM K584N K484N K504N...

Страница 105: ...104 VIDEO AUDIO BLOCK DIAGRAM K584N K484N K384N K284N K504N K304N...

Страница 106: ...105 PIF INPUT SELECTOR BLOCK DIAGRAM K584N K484N K384N K284N K504N K304N...

Страница 107: ...106 SYSCON SERVO BLOCK DIAGRAM K584N K484N K384N K284N K504N K304N SEG A SEG L SEG A SEG L SEG C SEG F G1 G8 G1 G8...

Страница 109: ...108 MAIN PCB 2HEAD 4HEAD...