Super Saver Bunsen Jet Brooder with SPI

11

6.2

Gas Hookup

6.2.1

Connection of gas hose to brooder

The brooder’s gas valve does not regulate the gas pressure. You must provide a

regulator to keep manifold pressure at the rated pressure (see ratings on page

one of this manual) for proper operation.

The following flowchart shows the minimum equipment for the operation of one

brooder. You may connect several brooders to one regulator, provided it can

maintain the rated pressure (see ratings on page one of this manual) to each

brooder connected to that regulator.

All brooders must be connected to the gas supply with an AGA approved gas

hose and fittings. An approved hose is available at your Cumberland dealer.

6.2.2

Checking Manifold Gas Pressure

To be performed by a CERTIFIED GAS TECHNICIAN only!

1.

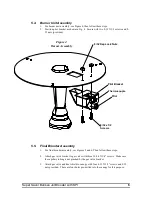

Turn OFF gas supply going to the brooder.

2.

Remove the manifold pressure tap plug from the gas control valve and

connect pressure gauge.

3.

Turn ON gas supply going to the brooder.

4.

Return brooder to operation and read pressure gauge. Note: To obtain an

accurate manifold pressure reading, the brooder must be cycled on and off

several times to stabilize the pressure regulator diaphragm.

5.

The gas pressure must be measured with all gas appliances that use the

same gas supply or piping in operation.

NOTE: The gas valve on this brooder is a non-regulating valve. You must

make all adjustments to gas pressure on an external regulator.

6.

If necessary, adjust the pressure regulator until acceptable manifold

pressures (found on the ratings plate and page one of the owners manual)

are read.

7.

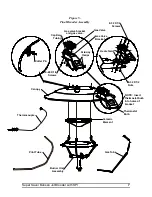

To adjust the manifold gas pressure, remove the cap screw located on the

top of the pressure regulator.

8.

Using a slotted tipped screwdriver, turn the adjustment screw clockwise to

increase gas pressure or counterclockwise to decrease gas pressure.

9.

Always replace cap screw and tighten firmly to prevent gas leakage.

10.

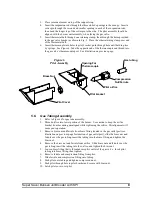

Turn OFF gas supply going to the brooder.

11.

Remove gas pressure gauge, reinstall manifold pressure plug.

12.

Turn ON gas supply going to the brooder.

13.

Return brooder to operation and observe through at least one complete

cycle to ensure brooder is operating properly.

14.

Perform gas leak test at outlet pressure tap plug. (Soap and water work

well.)