7

S

ection

2 — A

SSembly

& S

et

-U

p

(a)

NOTE: Standard skid shoes shown

for illustration.

(a)

(b)

(b)

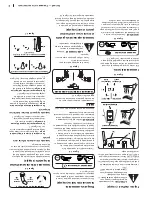

Figure 2-10

Shave Plate

NOTE:

This procedure applies to units equipped

with adjustable shave plates only.

To adjust the shave plate:

1.

Allow engine to run until it is out of fuel.

Do not attempt to pour fuel from the

engine.

2.

Carefully pivot unit up and forward so that

it rests on auger housing.

3.

Loosen rear skid shoe bolts (a) on both

sides of equipment housing and remove

carriage bolts and hex nuts which attach

shave plate to auger housing. See Figure

2-11.

4.

Slide shave plate downward into second

position. Reinstall and tighten all bolts

securely. See Figure 2-11.

(a)

(a)

Figure 2-11

5.

Adjust the skid shoes. See Skid Shoes on

page 7.

Chute Assembly Options

Refer to your applicable chute control style .See

Figure 3-1.

Overhead Chute Directional Control (With Flex

Shaft) (If Equipped)

The overhead chute directional control is

located at the rear of the unit towards the left

side under the handle panel. To change direction

in which snow is thrown, rotate chute directional

control. See Figure 2-12.

CHUTE DIRECTIONAL CONTROL

DISCHARGE

LEFT

DISCHARGE

RIGHT

Figure 2-12

Two-Way Chute-Pitch Control™

(If Equipped)

The two-way chute-pitch control is located on

the left side of the dash panel and is used to

control the distance of snow discharge from the

chute. Tilt the lever forward or rearward to adjust

the distance snow will be thrown. See Figure

2-13.

Two-Way Indexed Chute-Pitch Control

•

To Reduce the Distance Snow is Thrown:

Disengage lever from the current chute-

pitch setting. Move the lever forward to

pivot the upper chute down to the desired

pitch setting (a). See Figure 2-13.

•

To Increase the Distance Snow is Thrown:

Disengage lever from the current chute-

pitch setting. Move the lever rearward

to pivot the upper chute upward to the

desired pitch setting (a). See Figure 2-13.

TWO-WAY CHUTE-PITCH CONTROL

CHUTE TILT

DOWN

CHUTE TILT

UP

TWO-WAY INDEXED CHUTE-PITCH CONTROL

CHUTE TILT

DOWN

CHUTE TILT

UP

(a)

Figure 2-13

Auger Control Test

WARNING!

Prior to operating your

unit, carefully read and follow all

instructions below. Perform all

adjustments to verify your

equipment is operating safely and

properly.

Refer to Controls & Operation section (page 8)

for the location of auger control lever and check

adjustment as follows:

1.

When auger control lever is released and

in disengaged “UP” position, the cable

should have very little slack. It should NOT

be tight.

2.

In a well-ventilated area, start the snow

thrower engine. Refer to your Engine

Operator’s Manual.

3.

While standing in the operator’s position

(behind the unit), depress the auger

control lever to engage auger.

4.

Allow auger to remain engaged for

approximately ten (10) seconds before

releasing auger control lever. Repeat this

several times.

5.

With auger control lever in disengaged

“UP” position, walk to front of machine.

6.

Confirm that auger has completely

stopped rotating and shows NO signs

of motion. If auger shows ANY signs of

rotating, immediately return to operator’s

position and shut OFF engine. Wait for ALL

moving parts to stop before readjusting

auger control lever.

7.

To readjust the auger control cable, loosen

upper hex screw (a) on auger control

bracket. See Figure 2-14.

8.

Position bracket upward to provide more

slack (or downward to increase cable

tension). See Figure 2-14. Retighten upper

hex screw (a).

9.

Repeat Steps 2 through 6 to verify proper

adjustment has been achieved.

Auger Control

Bracket

(a)

Figure 2-14