12

S

ection

4— S

ervice

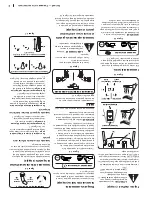

Auger Shaft

At least once a season, remove shear pins (a)

and cotter pins (b) from auger shaft(s). Spray

lubricant inside shaft and around spacers and

flange bearings found at either end of shaft(s).

See Figure 4-6.

(a)

(a)

(b)

(b)

NOTE:

Three Stage Augers Shown

(a)

(b)

Figure 4-6

IMPORTANT:

On 3-stage units, there

is an additional shear pin in the rear

accelerator.

Adjustments

Shift Rod (If Equipped)

If full range of speeds (forward and reverse)

cannot be achieved, adjust shift rod as follows:

1.

Place shift lever in fastest forward speed

position.

2.

Remove cotter pin (a) and washer (b) from

adjustment ferrule on shift rod and pull it

out from shift lever. See Figure 4-7.

(a)

(b)

Figure 4-7

3.

Pivot shift bracket downward as far as it

will go. See Figure 4-8.

4.

Rotate ferrule up or down on shift rod as

necessary until it lines up with upper hole

in shift lever. Refer to Figure 4-7 inset.

5.

Insert the ferrule into the upper hole and

secure with the washer and cotter pin.

Auger Control

Refer to Assembly & Set-up section for

instructions on adjusting auger control cable.

Skid Shoes

Refer to Assembly & Set-up section for

instructions on adjusting skid shoes.

Figure 4-8

Drive Control (If Equipped)

When drive control lever is released and in

disengaged “UP” position, cable should have

very little slack. It should NOT be tight.

NOTE:

If excessive slack is present in drive cable

or if unit’s drive is disengaging intermittently

during operation, the cable may be in need of

adjustment.

Check adjustment of drive control lever as

follows:

1.

With drive control lever released, push

unit gently forward. It should roll freely.

2.

Engage drive control lever and gently

attempt to push the unit forward. The

wheels should not turn. The unit should

not roll freely.

3.

If equipped with a shift lever, with drive

control lever released, move shift lever

back and forth between the R2 position

and the F6 position several times. There

should be no resistance in the shift lever.

If any of the above tests failed, the drive cable is

in need of adjustment. Proceed as follows:

1.

Shut OFF engine. Refer to the Engine

Operator’s Manual.

2.

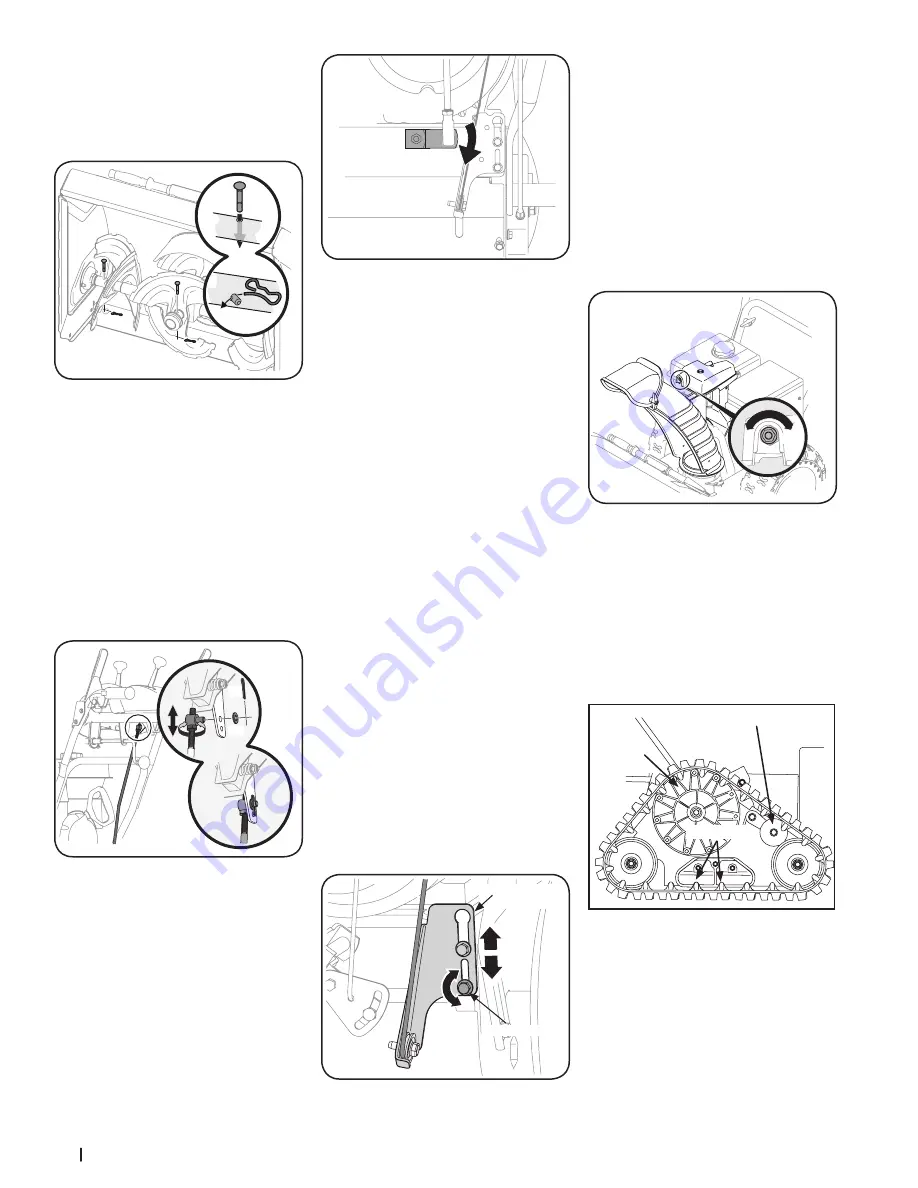

Loosen lower hex screw (a) on drive cable

bracket. See Figure 4-9.

3.

Position bracket upward to provide more

slack (or downward to increase cable

tension).

4.

Retighten upper hex screw.

5.

Check adjustment of drive control lever

as described above to verify proper

adjustment has been achieved.

(a)

Drive Cable

Bracket

Hex Screw

Figure 4-9

Chute Assembly (Overhead Chute Control) (If

Equipped)

If chute fails to remain stationary during

operation, pre-load of chute can be adjusted

by tightening hex nut found on front of chute

control assembly.

1.

To increase preload, tighten

hex nut (a) clockwise in ¼ turn intervals.

The chute control rod will need to be held

stationary when tightening the nut. See

Figure 4-10.

2.

If chute directional control is difficult to

crank, decrease preload by loosening hex

nut counter-clockwise in ¼ turn intervals.

(a)

Figure 4-10

Continuous Tracks

The snow thrower is equipped with an auto-

tensioner on both the left and right sides. The

system is designed to maintain constant tension

on both tracks. However, if the snow thrower

fails to propel itself because the track wheel is

“jumping” drive lugs, the tracks are too loose

and are in need of adjustment. See an authorized

Service Dealer to have the tracks properly

adjusted. See Figure 4-11.

Track

Wheel

Auto-tensioner

Drive Lugs

Figure 4-11