INSTALLATION & OPERATION MANUAL 10121 REV 0 (04/21)

PAGE

6

OF 20

Self-Generating Steam Jacketed Counter Tilting Kettles

U

NPACKING

IMMEDIATELY INSPECT FOR SHIPPING DAMAGE

Immediately after unpacking the steamer, check for possible shipping damage. If the steamer is found to be damaged,

save the packaging material and contact the carrier within 15 days of delivery.

I

nstallation

I

NSTALLATION

I

nstallation

I

nstructions

Immediately after unpacking, check for possible shipping damage. If the kettle is found to be damaged, save the

packaging materials and contact the carrier within 15 days of delivery.

1. The kettle must be installed in accordance with:

1. State and/or local codes.

2. In the USA, the National Electrical Code, ANSI/NFPA-70 (latest edition). In Canada, the Canadian Electrical

Code, Part 1, CSA Standard C22.1 (latest edition).

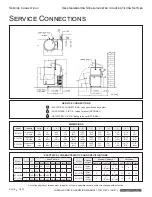

2. Position appliance on counter allowing sufficient rear clearance from wall to tilt freely and completely without obstruction.

3. Mark four corner locations of appliance base.

4. Remove appliance from counter and locate position of 4 holes as per Figure 1. Drill four 7/16” diameter holes.

5. Apply a continuous bead of Silastic or other equivalent sealant along the complete perimeter edge of the

appliance base.

6. Use 5/16-18 Hex Cap Screws with suitable flat washers to bolt down. Screw length must be 1-1/4 long plus

counter top thickness.

7. Wipe off excess sealant.

8. A Control Box with power supply equivalent to Electrical Rating of appliance should be located conveniently nearby.

WARNING

ELECTRICAL GROUNDING INSTRUCTIONS

Electrical and grounding connections must comply with the applicable portions of the National Electrical

Code and/or other local electrical codes.

WARNING

Disconnect electrical power supply and place a tag at the disconnect switch to indicate you are on the circuit.

9. A waterproof electrical connection from power supply to

console housing must be provided.

10. Ground appliance to terminal provided inside console

housing.

11. Turn power ON and check for proper operation.

Figure 1