15

English

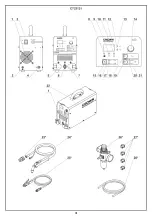

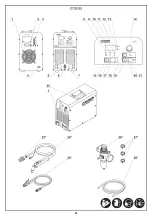

•

inspect the condition of all cables and replace the

cable where damage is found;

•

inspect the condition of hose

28

, replace it if

damage is found;

•

ensure that there is no leakage during air delivery;

•

check the condition of cutting torch

24

and earth

clamp

25

, if they are damaged, replace them�

•

Before switching on the machine, ensure that cutting

torch nozzle and earth clamp

25

do not touch each other�

•

After the machine is switched on, make sure that the

built-in cooling fan is working - the air will be blowing

from vent holes

1

(on the back of the machine)�

Switching the machine on / off

Switching on:

Move switch

3

into the "On" position (indicator

8

will then

light up and the built-in cooling fan will start rotating)�

Switching off:

Move switch

3

into the "Off" position�

Design features of the machine

Temperature protection

Temperature protection prevents machine damage,

switching it off in case of overheating� When tempera-

ture protection goes on, indicator

10

lights up� Do not

switch the machine off, let it cool down and do not con-

tinue operation until then�

Button F1 (torch operation mode selection)

Press button

15

(F1) to select one of the two torch

24

operation modes:

•

2T mode (two-stroke; when this mode is

selected, indicator

16

lights up) - press and hold

button

42

to turn on torch

24

� During the operation,

continue to hold button

42

� Release button

42

to

turn off torch

24

;

•

4T mode (four-stroke, when this mode is selected,

indicator

17

lights up) - press and release button

42

to turn on torch

24

� During the operation, there is no

need to hold button

42

� Press and release button

42

again to turn off torch

24

�

Button F2 (cutting mode / setting parameters)

Press button

19

(F2) to select air flow and air pressure

setting mode or cutting mode:

•

air flow and air pressure setting mode (when this

mode is selected, indicator

20

is lit) - no current is

applied to torch

24

� Press button

42

(as described

above) and adjust air pressure and air flow;

•

cutting mode (when this mode is selected,

indicator

21

is lit) - the machine is ready for

operation; when torch

24

is turned on, indicator

9

also lights up, indicating that current is supplied to

torch

24

�

Button F3 (current adjustment / purge time adjust-

ment)

Press button

18

(F3) to select current adjustment

mode or post-cutting air purge time adjustment mode:

•

amperage adjustment mode - when this mode

is selected, indicator

13

is lit� To change amperage

setting, turn regulator

14

(the set value is shown on

display

11

);

•

post-cutting air purge time adjustment mode (to

cool torch

24

) - when this mode is selected, indica-

tors

12

is lit� To change purge time, turn regulator

14

(the set value is shown on the display

11

)� To con-

firm the set purge time, press button

18

again�

Recommendations on the machine op-

eration

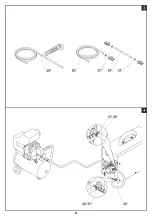

General operation recommendations (see fig. 7-8)

The recommendations below apply to all

machines connected through a socket con-

nector. In the case of stationary connection

the machine assembly and power

network

connection will be done beforehand.

•

Place the machine in an even, dry, not vibrating

surface observing all above-mentioned safety proce-

dures�

•

Connect the machine to the compressor, as de-

scribed above�

•

Connect grounding wire

29

, earth clamp

25

and

torch

24

to the machine�

•

Fix earth clamp

25

on the cleared section of the

component, as close to the cutting place as possible�

Attention: don't fix earth clamp 25 on the work

-

piece section that will be cut off.

•

Connect the machine to the mains and switch it on�

•

Switch on the compressor�

•

Adjust the operating parameters as described

above. Select the torch mode, air flow and pressure,

current and post-cutting air purge time�

•

Set a delivery air pressure, for this purpose move

valve

45

upwards, turning valve

45

, adjust the pres-

sure (observe manometer

32

) and move valve

45

downwards to fix a set pressure value (see fig. 8.1).

•

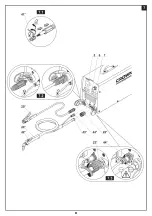

Touch the workpiece with nozzle tip

38

and turn on

torch

24

as described above (depending on selected

torch

24

operation mode ) - the high-frequency device

will ignite the cutting arc between electrode

40

and

the workpiece, then raise torch

24

over the workpiece

at ~1 mm�

•

If you start cutting from the workpiece edge, hold the

cutting torch vertically and move it steadily along the

cutting line (see fig. 9.1). Choose the proper cutting

speed according to the workpiece thickness and cho-

sen current rate� If the speed is chosen properly, the

arc, coming from the workpiece low surface, should

have the angle of the slope opposite to the moving di-

rection by about 5°-10° (see fig. 9.2).

•

If the cutting torch moves too fast, the arc won't

be able to cut the workpiece, and sparks will be ob-

served from the cutting torch (see fig. 9.3).

•

If the cutting torch moves too slowly, then molten

metals rollers will stay on the cut edges from the low

side of the workpiece (see fig. 9.4).

•

If you start cutting from the middle of the workpiece,

start cutting with an angled cutting torch, then lift it up

steadily, as shown in fig. 9.5. This method prevents

thrust generation of the arc or separate particles,

which can result in damage of the nozzle opening and

a decrease in the machine's functionality�

•

After turning the torch

24

off, the air supply contin-

ues for a while, which cools the torch (use F3 button to

set blow time as described above)�

Содержание CT33131

Страница 1: ......

Страница 3: ...3 ...

Страница 4: ...4 ...

Страница 5: ...5 ...

Страница 6: ...6 ...

Страница 7: ...7 ...

Страница 8: ...8 ...

Страница 9: ...9 ...

Страница 49: ...49 ...

Страница 50: ...50 ...

Страница 51: ...51 ...

Страница 52: ...52 ...

Страница 53: ...53 ...

Страница 54: ...54 ...

Страница 55: ...55 ...

Страница 56: ...56 ...

Страница 57: ...57 ...

Страница 58: ...58 ...

Страница 59: ...59 ...

Страница 60: ...60 ...

Страница 61: ...61 ...

Страница 62: ...62 ...

Страница 63: ...63 ...

Страница 64: ......