29

28

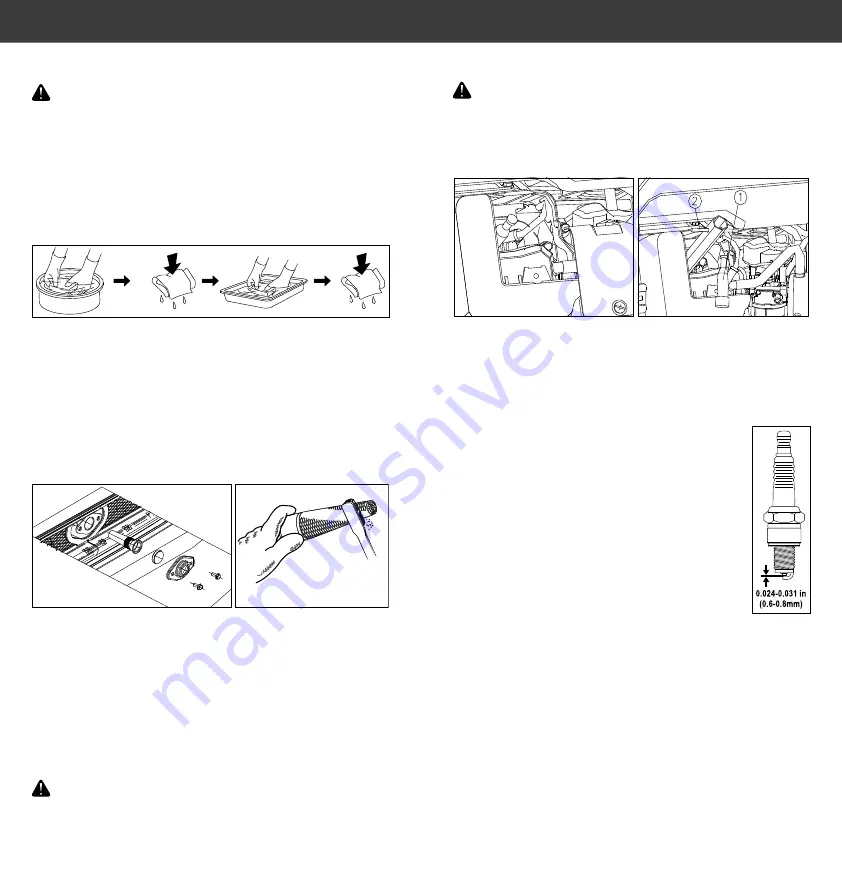

AIR FILTER CLEANING

NOTICE: Do not operate the engine without an air cleaner

element as this will cause damage to the inner parts of

the engine. In unusually dusty conditions regular cleaning

or replacing is required.

The foam filter element of the dirty air filter will restrict the air

flow to the fuel system and reduce the engine performance.

If the generator is used in a dusty area, the maintenance

frequency of the air filter’s foam filter element is higher than

that in the maintenance requirements.

1. Wash the filter element in warm soapy water and let it dry

naturally, or clean and dry it in a non – flammable solvent.

2. Dip the filter element into clean oil and squeeze out excess

oil. If there is too much oil left in the filter element, start

the engine and the engine will smoke.

3. Use a damp cloth to remove dirt from the inside of the air

filter’s cover. Take care to prevent dust from entering the

air ducts which leads to the fuel system.

Spark Arrester

The spark arrester must be cleaned every 100 hours to

maintain engine performance. Ensure exhaust outlet and

engine is cold before cleaning and maintenance.

To remove and clean the spark arrester.

1. Loosen two M5x12 pan head bolts and remove mounting

cover, muffler mesh cover and spark collector.

2. Clean the muffler’s mesh cover and the cumulative carbon

on the spark collector with a steel wire brush.

3. Refit and tighten the spark arrester.

NOTICE: Clean with steel wire brush gently to avoid

damage or scratch to muffler mesh and spark arrester.

The spark arrester must not be broken or cracked. If it is

damaged, it must be replaced.

Spark Plug

NOTICE: Incorrect spark plug can cause damage to the

engine.

To replace or clean the spark plug use the spark plug spanner

kit supplied. Allow engine to cool before attempting to

remove the spark plug.

1. Rotate the lock 90° counterclockwise, and open left

maintenance door.

2. Loosen bolt of spark plug’s maintenance cover and remove.

3. Remove the spark plug cap, remove dirt and dust from

around the spark plug.

4. Use the spark plug spanner and rotate counter-clockwise

and remove the spark plug.

5. Check the spark plugs. Replace the spark plug,

if the electrode is worn or burnt, or if the

insulator is cracked or broken. Standard spark

plug: NGK BPR7ES, clearance of spark plug:

0.6-0.8mm.

6. After ensuring that the spark plug is in good

condition, fix the spark plug gently to the

head of the cylinder by hand to prevent

thread damage caused by force.

7. After the spark plug is fixed, tighten it with the

spark plug spanner. If the used spark plug is to

be reinstalled, tighten 1/8-1/4 circle manually

after fixing the spark plug and before

tightening it to the specified position. If the newly installed

spark plug is to be reinstalled, tighten 1/2 circle manually

after fixing the spark plug and before tightening it to the

specified position. Torque: 13.3 LBS. Ft (18 N.M, 1.8kg.m)

8. Install the spark plug cap.

9. Install spark plug maintenance cover and tighten

maintenance cover’s bolts.

10. Close the left maintenance door, and rotate the lock 90°

clockwise.

NOTE

: Spark Plug Type: NGK BPR7ES

NOTE

: If the spark plug is installed without torque wrench, a

better estimation method is to tighten 1/4-1/2 circle

manually, but the spark plug should be tightened to the

specified torque.