3

www.cranecpe.com

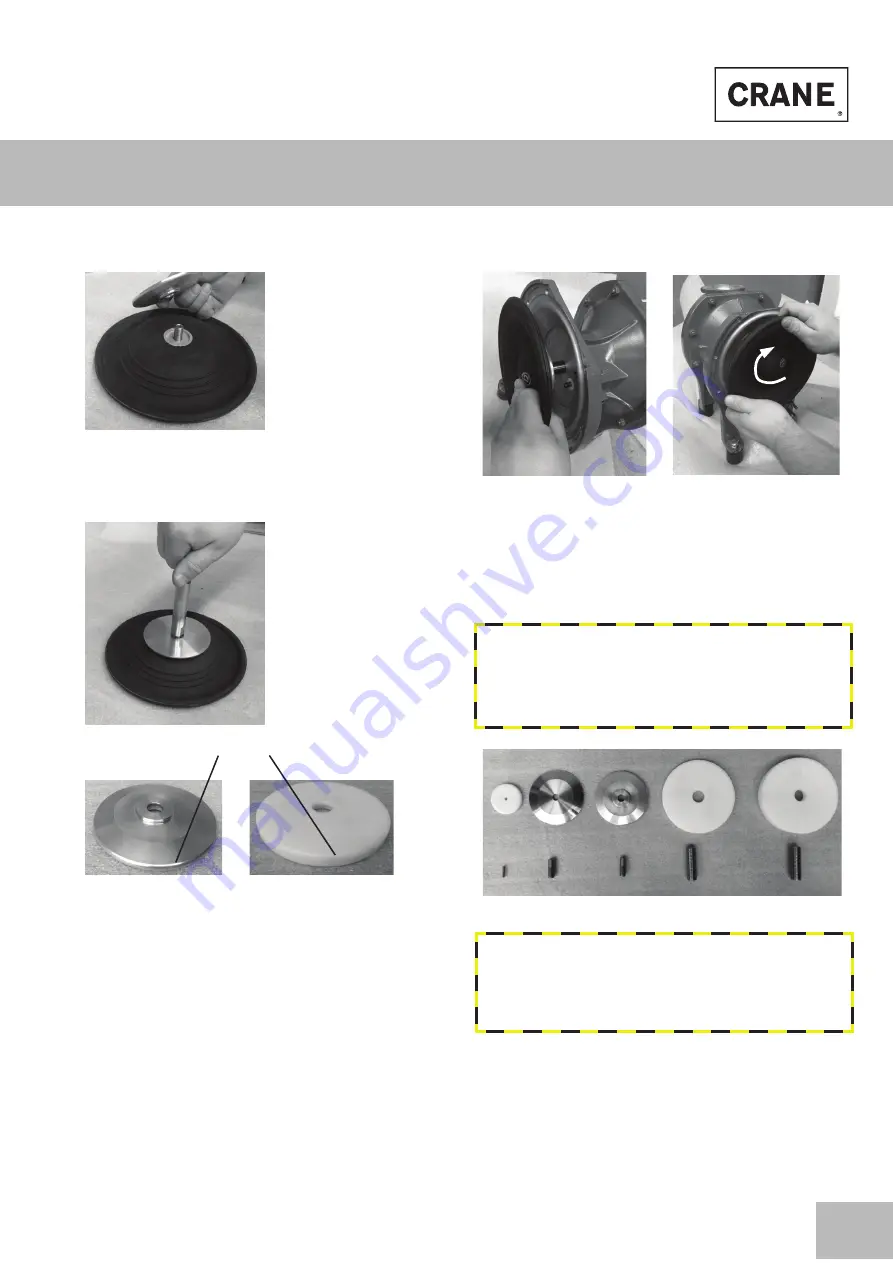

Replacing the diaphragms

Place switch disc on top. The radius or the chamfer is

mounted in the direction of the diaphragm´s air side.

(Pic. 8)

Pic. 8

Screw piston rod onto set screw and tighten by hand

(nopped E4® assembly unit including the piston rod, see

Pic. 9)

Pic. 9

Pic. 10

Before assembling the diaphragm unit, check whether

other parts of the center block need to be exchanged

(e.g. defective or dirty seals, piston rod bearings, defect

air valve, pilot rod or silencer). If required, exchange these

accordingly.

Slide in the nopped E4® assembly unit into the center block

(picture 11) and fix the second diaphragm with switch disc

on the opposite side (mount the threaded pin in the second

nopped E4® diaphragm as shown in picture 7). Tighten the

second diaphragm by hand (picture 12). At the same time,

lock the piston rod with a wrench.

Install pump chambers, insert valve seats and balls (check

for any damages and if required replace), mount suction

and discharge manifolds as per the DEPA® IOM.

Pic. 11

Pic. 12: Tighten by hand

The DEPA® nopped E4® starter kit contains

•

2 diaphragms

•

2 switch discs

•

2 set screws

•

Sealings for air control area of pump

Note:

The DEPA® nopped E4® starter kit includes switch discs

and set screws in the matching sizes. Switch disc material for

sizes 15, 50 and 80 is POM, for the sizes 25 and 40 aluminium.

Each switch disc has a different thickness. The set screws are

available in three sizes (15, 25 & 40 and 50 & 80)

Pic. 13: Switch discs and set screws

Note:

For DEPA® pumps with nopped E4® diaphragms a new

pump coding system is used. To recognize a retrofitted DEPA®

pump, please use the sticker enclosed in this manual and

attach it, next to the nameplate area. Upon request we can

supply you with a new nameplate.

Chamfer radius

Aluminium switch disc

POM switch disc

15 25 40 50 80