19

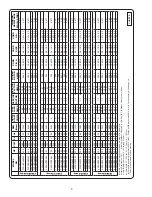

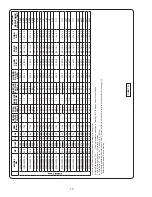

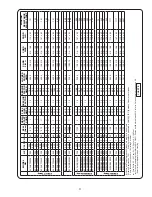

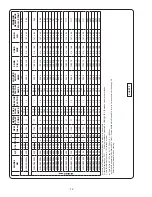

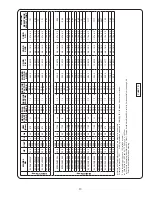

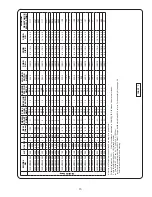

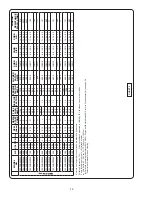

TABLE 1

TEMPERATURE SENSOR ELECTRICAL RATINGS

Volts

Continuous

Amperes

Inrush

Amperes

110-120

3.00

30.0

220-240

1.50

15.0

440-480

0.75

7.5

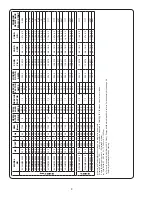

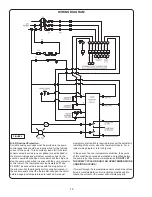

B-4.4) Moisture Sensors:

A normally open (N/O) detector is installed in the pump

seal chamber, which will detect any moisture present,

and a continuity test resistor built into the motor. The

test resistor is rated 1 watt at 330K ohms. The moisture

sensors

MUST

be connected to moisture detector

control in the control panel which includes a continuity

test circuit, see Figure 4 for typical wiring diagram. The

normally closed (N/C) contact of the moisture detector

MUST

be connected in series with the stop button of the

pilot circuit of the magnetic motor controller. Wiring must

be provided from the moisture detector sensor probe

leads of the motor designated W1 and W2 to terminals 9

and 10 of the 2800-XXX control. Terminal pair 1-2 must

be continuously energized from an A-C supply line of

electrical characteristics shown on the data table. In the

event of moisture detection, the pump should be pulled

and the source of the failure located and repaired.

IF

MOISTURE DETECTION HAS OCCURRED, SCHEDULE

MAINTENANCE AS SOON AS POSSIBLE !

B-4.5) Control Panel and Electrical System:

The control panel and the electrical system

MUST

be

properly designed and wired to include at least, but not

limited to the following;

a. Proper grounding per NEC.

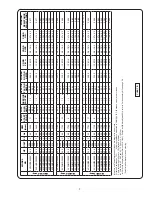

b. A temperature sensing circuit (see Fig. 4)

c. A moisture detection circuit with continuity test

circuit (see Figure 5)

d. A level control system.

e. A main power manual disconnect and lock out.

f. A motor starter and overload system.

B-5) When Used with a Variable Speed Drive:

Maximum turndown should not exceed 2:1. Drive should be

set to operate in constant torque mode.

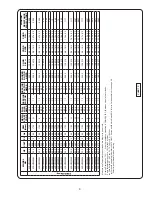

It is advisable that all three phase control panels be

purchased from the factory.

If a panel is to be supplied locally, it is recommended that

the Crane Pumps & Systems Pump Monitor Relay (P/N

134667) be used to perform the control circuit functions for

the Temperature and Moisture Sensor Monitoring described

in sections B4.3 and B4.4. The Pump Monitor Relay was

designed to perform these functions in a compact module

that can be base or panel mounted and is resistant to noise

issues found with some VFD’s. Indicator lights on the front

display notify the operator in the event of a fault condition

for either temperature, moisture or both. Normally open and

normally closed contacts are flexible to accommodate nearly

any wiring scenario and the moisture sensor sensitivity can

be adjusted to prevent nuisance alarms.

SECTION: C START-UP OPERATION

C-1) Check Voltage and Phase:

Before operating pump, compare the voltage and phase

information stamped on the pump’s identification plate to the

available power.

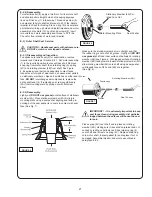

C-2) Check Pump Rotation:

Before putting pump into service for the first time, the motor

rotation must be checked. Improper motor rotation can result

in poor pump performance and can damage the motor and/

or pump. To check the rotation, suspend the pump freely,

momentarily apply power and observe the “kickback”.

“Kickback” should always be in a counter-clockwise direction

as viewed from the top of the pump motor housing and will

always be in the opposite direction of the rotation arrows

cast in the pump volute.

C-2.1) Incorrect Rotation for Three-Phase Pumps:

In the event that the rotation is incorrect for a three-phase

installation, interchange any two power cable leads at

the control box. Recheck the “kickback” rotation again by

momentarily applying power.

C-2.2) Test Procedure For Moisture Sensor Control:

With a moisture detection control, a normally closed push

button and neon indicating lamp is typically provided as a

means of checking the moisture sensing components. When

the push button is depressed, the indicating lamp will be

illuminated to indicate (A) power is supplied to the control,

(B) the control is operative, and (C) wiring to the moisture

sensing probes in the motor is intact. This procedure should

be performed periodically to confirm integrity of the circuit.

C-3) Start-Up Report:

Included at the end of this manual is one start-up report

sheet, this sheet is to be completed as applicable. Return

a copy to Barnes and store the second in the control panel

or with the pump manual. It is important to record this data

at initial start-up since it will be useful to refer to should

servicing the pump be required in the future.

C-3.1) Identification Plate:

Record the numbers from the pump’s identification plate on

the START-UP REPORT provided at the end of the manual

for future reference.

Содержание BARNES 10XSHD

Страница 48: ...Notes ...