18

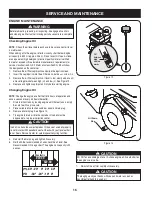

SERVICE AND MAINTENANCE

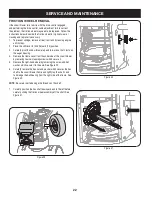

Wheels

At least once a season, remove both wheels. Clean and coat the axles

with a multipurpose automotive grease before reinstalling wheels.

Chute directional Control

Once a season, lubricate the eye bolt bushing and the spiral with 3-in-1

oil.

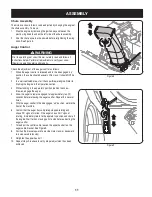

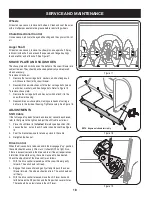

auger shaft

At least once a season, remove the shear pins on auger shaft. Spray

lubricant inside shaft, and around the spacers and flange bearings

found at either end of the shaft. See Figure 17.

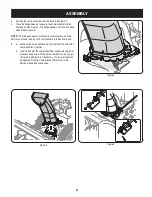

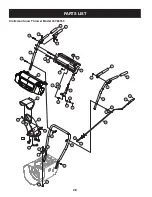

sHaVe PLate and skid sHoes

The shave plate and skid shoes on the bottom of the snow thrower are

subject to wear. They should be checked periodically and replaced

when necessary.

To remove skid shoes:

Remove the four carriage bolts, washers, and hex flange nuts

1.

which secure them to the snow thrower.

Reassemble new skid shoes with the four carriage bolts (two on

2.

each side), washers, and hex flange nuts. Refer to Figure 18.

To remove shave plate:

Remove the carriage bolts and hex nuts which attach it to the

1.

snow thrower housing.

Reassemble new shave plate, making sure heads of carriage

2.

bolts are to the inside of housing. Tighten securely. See Figure 18.

adjUstments

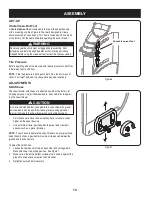

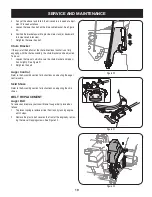

shift Cable

If the full range of speeds (forward and reverse) cannot be achieved,

refer to the figure to the right and adjust the shift cable as follows:

Place the shift lever in the

1.

fastest

forward speed position (F6).

Loosen the hex nut on the shift cable index bracket. See Figure

2.

19.

Pivot the bracket downward to take up slack in the cable.

3.

Retighten the hex nut.

4.

drive Control

When the drive control is released and in the disengaged “up” position,

the cable should have very little slack. It should NOT be tight. Also,

if there is excessive slack in the drive cable or if the unit experiences

intermittent drive while using, the cable may need to be adjusted.

Check the adjustment of the drive control as follows:

With the drive control released, push the snow thrower gently

1.

forward. The unit should roll freely.

Engage the drive control and gently attempt to push the snow

2.

thrower forward. The wheels should not turn. The unit should not

roll freely.

With the drive control released, move the shift lever back and

3.

forth between the R2 position and the F6 position several times.

There should be no resistance in the shift lever.

Figure 18

NOTE: Augers not shown for clarity.

Figure 19

Figure 17

Содержание 247.88955

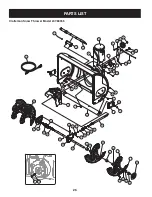

Страница 32: ...32 PARTS LIST Craftsman Engine Model ZS365 SUA For Snow Thrower Model 247 88955 ...

Страница 67: ...NOTAS 67 ...