17

THREADS CUTTING

Several different threads can be cut using

the proper combination of gears and

settings.

Set the compound slide to the proper angle

required for the cut and align the tip of the

cutting tool with the center of the work-

piece.

Engage the thread dial with the leadscrew

accodring to the chart (figure-19).

Install the gears according to the thread

charts (figure-17 & 18) to get the required

RPM for the job.

Turn the spindle ON and select the RPM

and make sure that the carriage is moving

to the correct direction for cutting.

Figure-19 Thread dial chart

MAINTENANCE

During the life of your machine, you will

need to practice some regular maintenance

to keep your lathe in peak performance

condition.

Check your machine daily for the following

before use:

* Loose mounting nuts and bolts

* Worn or damaged cord

* Damaged parts

* Any other unsafe condition

CLEANING

Treat the machine with care, keep it clean

and grease and lubricate it regularly. Only

through good care you can be sure that the

working quality of the machine will remain

constant.

Oil, grease and cleaning agents are

pollutants and must not be disposed off

through the drains or in normal garbage.

Dispose of those agents in accordance with

current local environmental regulations.

Cleaning rags impregnated with oil, grease

and cleaning wool in a suitable closed

vessel and disposed of in an

environmentally sound way. Do not put

them with normal garbage.

During operation, the chips which fall onto

the sliding surface should be cleaned in a

timely fashion. Frequent inspections should

be made to prevent chips from falling into

the position between the carriage and bed

way.

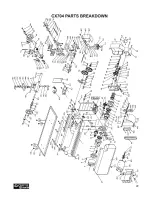

Содержание CX704

Страница 1: ...CX704 7 x 12 MINI METAL LATHE User Manual ...

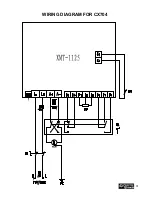

Страница 21: ...21 WIRING DIAGRAM FOR CX704 ...

Страница 22: ...22 ...