Installation

6

Installation

1. Study Figure 2 for suggested layouts. The Easy-Install

layout works better for deeper sumps and allows a

smaller diameter sump (diameter 13-1/2” or larger,

depth more than 22”).

The Alternate layout works better for wider, shallower

sump pits (diameter 18” or larger, depth 18-22”).

The Alternate layout will require that you purchase

(2) 1-1/4” x 90° elbows and (2) 1-1/4” x close pipe

nipples.Other layouts may require more pipe fittings.

2. Find the high water level mark you made on the

discharge pipe in Setup. Cut the pipe at this point

and set the cut-off piece aside for use later. Clean up

and debur the cut ends.

3. Wrap the threads of the Battery Back Up (BBU)

pump and the 1-1/4” x close nipple with

1-1/2 – 2 turns of PTFE pipe thread sealant tape (see

Figure 2). Leave the first thread free of tape and wrap

clockwise (

).

4. Thread the tee, the close nipple, the 1-1/4” x

1-1/4” check valve, and the BBU pump together.

To get them tight, hold the pump and insert a large

screwdriver down through the tee and tighten

the whole assembly with the screwdriver. Do not

overtighten! When the assembly is tight, the pump

and tee should align vertically (no twist – see

Figure 2).

5. Glue the cut-off piece of pipe (which you set aside in

Step 2) into the top of the tee.

NOTICE If your discharge pipe is 1-1/4” inch, glue

one of the reducer bushings supplied with the system

into the tee, then glue the pipe into the bushing.

6. Look at your primary pump to determine if you have

a check valve in or near the pump discharge. If not,

install the auxiliary check valve in the bottom arm

of the tee and install the slip coupling on the check

valve (see Figure 2). For 1-1/4” discharge pipe, glue

the remaining reducer bushing into the slip coupling.

NOTICE If the primary pump assembly already

includes a functioning check valve, do not use the

auxiliary check valve included in the BBU system.

You need one check valve between the primary

pump and the tee (to prevent backflow from either

pump into the sump pit), but two check valves will

restrict the pipe too much.

7. Trial Fit (no glue yet): Place the primary pump

assembly back in the sump pit and add (dry) the tee/

check valve/BBU pump assembly to it. If necessary,

also include the 1-1/2 x 1-1/4 reducer bushing and

the slip coupling and auxiliary check valve (see

NOTICE, above).

8. Measure the assembly against the hanging upper

discharge pipe (where you cut it previously). Mark

the discharge pipe coming up from the tee 1/4”

below the point of overlap (that is, you should have

an air gap of 1/4” after you cut the pipe). Don’t cut

anything yet.

9. Study the assembly in the pit for a moment and then

adjust it so that nothing interferes with the primary

pump or its switch. Mark the joints with a permanent

marker so that you can realign everything after you

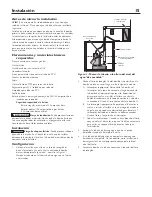

pull it out of the pit for gluing (see Figure 3).

NOTICE Take your time with this - it takes care but

isn’t very difficult. Be sure you leave enough room

for the BBU pump’s vertical switch. Mark everything

that might move!

10. After you have marked everything, remove the

assembly from the pit.

11. Cut off the vertical discharge pipe at the cut point

you marked in Step 8. Be sure you are cutting on the

correct mark!

12. Recheck the alignment and glue up all the joints on

the primary pump assembly.

NOTICE You may need to support the assembly,

which won’t balance very well, in order to preserve

the alignment while gluing it. Check this before you

start gluing. Another pair of hands may help here!

13. After the glue has set, slide the hose coupling and its

clamps down over the assembled discharge pipe. If

the pipe is 1-1/4”, be sure to use the two reducing

inserts included with the coupling.

5762 0108

Figure 3 - Mark joints for gluing

Содержание CL1800DC

Страница 24: ......