13

13

.

Installing front and rear cast baf

fl

es, heat plates.

NOTE: Grate frames and brick will slide forward and

backward to allow baf

fl

e to

fi

t. Install front cast baf

fl

e

using two (2) 5/16 bolts, nuts & washers (7/16 wrench

will be needed). Place the side of the baf

fl

e that has

the two ribs against the front weld of the

fi

rebox. Do

not tighten bolts yet. Place the rear cast baf

fl

e to

the back of the

fi

rebox but do not attach the bolts at

this time.

14.

Now slip the rear heat plate in behind the rear baf

fl

e.

Attach heat plate to the

fi

rebox by using two (2) 5/16

bolts, nuts & washers. First, line up the top holes and

tighten bolts. Secondly, line up the holes in the rear

baf

fl

e and the heat plate with the

fi

rebox and attach

by using two (2) 5/16 bolts, nuts & washers. Tighten

all four (4) bolts. NOTE: to reach rear bolts you may

fi

nd it easier to put your arm through the

fl

ue outlet

rather than to reach through the feed door.

15

.

Installing smoke damper rod to sliding smoke damper.

First, insert rod through hole above feed door and

push forward.

16

.

Next working through the

fl

ue hole behind furnace, line

up rod between the two posts on the sliding smoke

damper. Then line up the three (3) holes for cotter

pin insertion, this procedure will test your patience.

It’s helpful to have a

fl

ashlight and another person

positioning the rod.

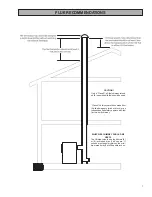

ASSEMBLY ILLUSTRATIONS

Содержание 24A

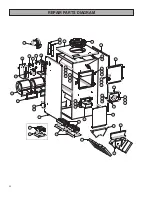

Страница 22: ...22 REPAIR PARTS DIAGRAM ...

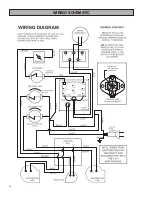

Страница 24: ...24 WIRING SCHEMATIC ...

Страница 25: ...25 NOTES ...

Страница 26: ...26 NOTES ...

Страница 27: ...27 NOTES ...