Page 10

SRP 003-304 • Issue 9 • July 2004

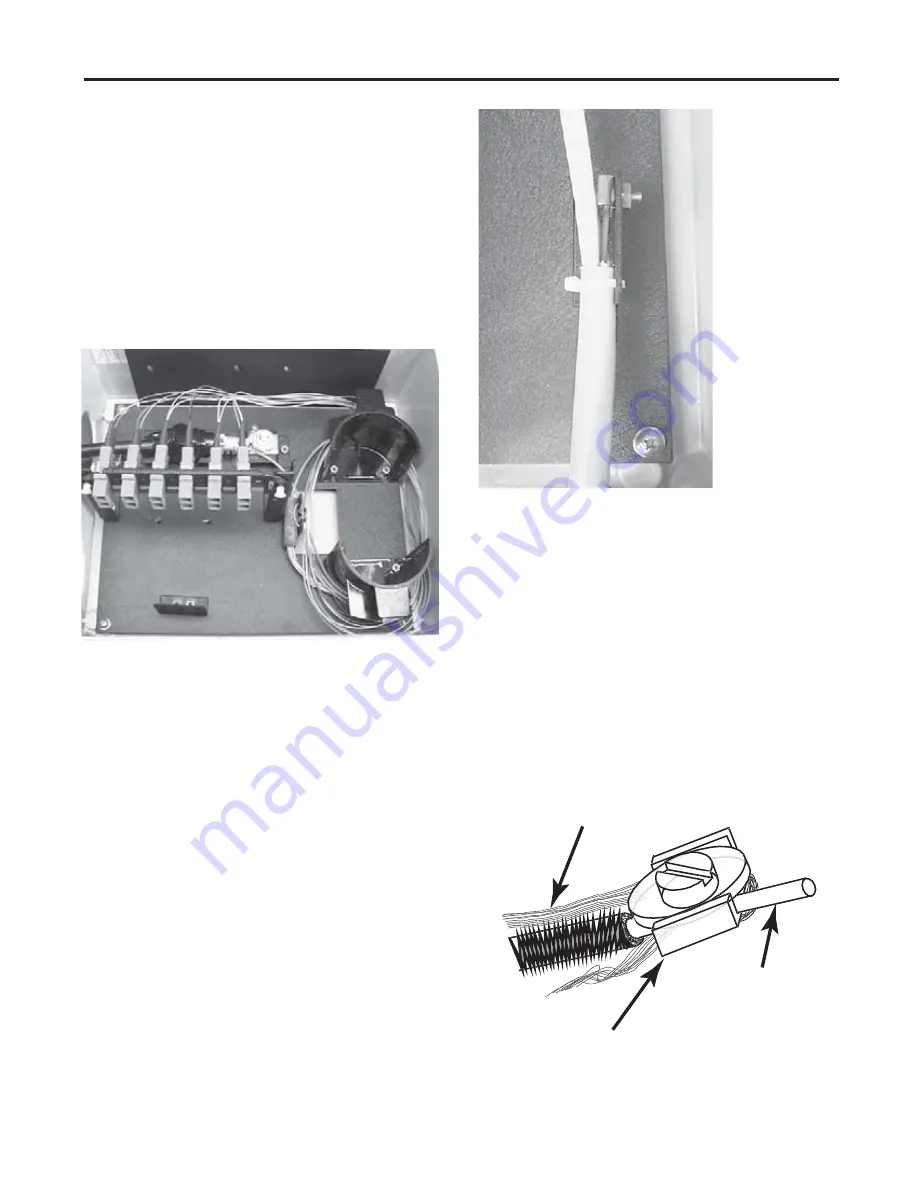

Figure 22

12.5

Route the fiber in the fan-out tubing

around the guides and plug connectors into the

connector panel (Figure 21). Refer to the

previous connector care instructions to avoid

damaging the connectors during installation.

12.6

Label the connector end of the pigtail

with its port identifier. Record information

appropriately on the record label inside the

front door.

NOTE:

Accurate record keeping is imperative

for an organized installation.

13. Installing Drop Cables

13.1

The EDC is designed to accept up to six

drop cables. Feed the drop cable through the

fitting you installed on the right at the base of

the closure.

NOTE:

Drop cable subunit lengths should be

approximately 130 cm (51 inches) in length in order

to provide two loops of fiber slack around the radius

guides.

13.2

If the drop cables do not include central

members, secure the cables to the bracket using

a loosely tightened cable tie. When central

member strain-relief is necessary, remove the

drop cable strain-relief bracket and secure the

cable to the bracket using a cable tie as shown

(Figure 22).

a) Install the 8-32x5/8 screw from the front

side of the strain-relief bracket through the

flat washer and U-shaped washer. Loosely

install the hex nut.

b) Insert the central member of the cable

between the flat washer and the U-shaped

washer (Figure 23).

c) From the front side of the strain-relief

bracket, wrap the strength member yarn in a

clockwise direction around the screw and

under the U-shaped washer (Figure 23).

d) Tighten the hex nut.

e) If the central member is metallic, place the

eye of a ground wire (#6 AWG, purchased

separately in appropriate length from any

electrical supply store) under the U-shaped

washer or under the flat washer.

Figure 21

Figure 23

Strength-Member Yarn

U-Shaped Washer

Central Member