© 2009 CONTRIVE • B1401|400.EN

0211

10

www.contrive.it

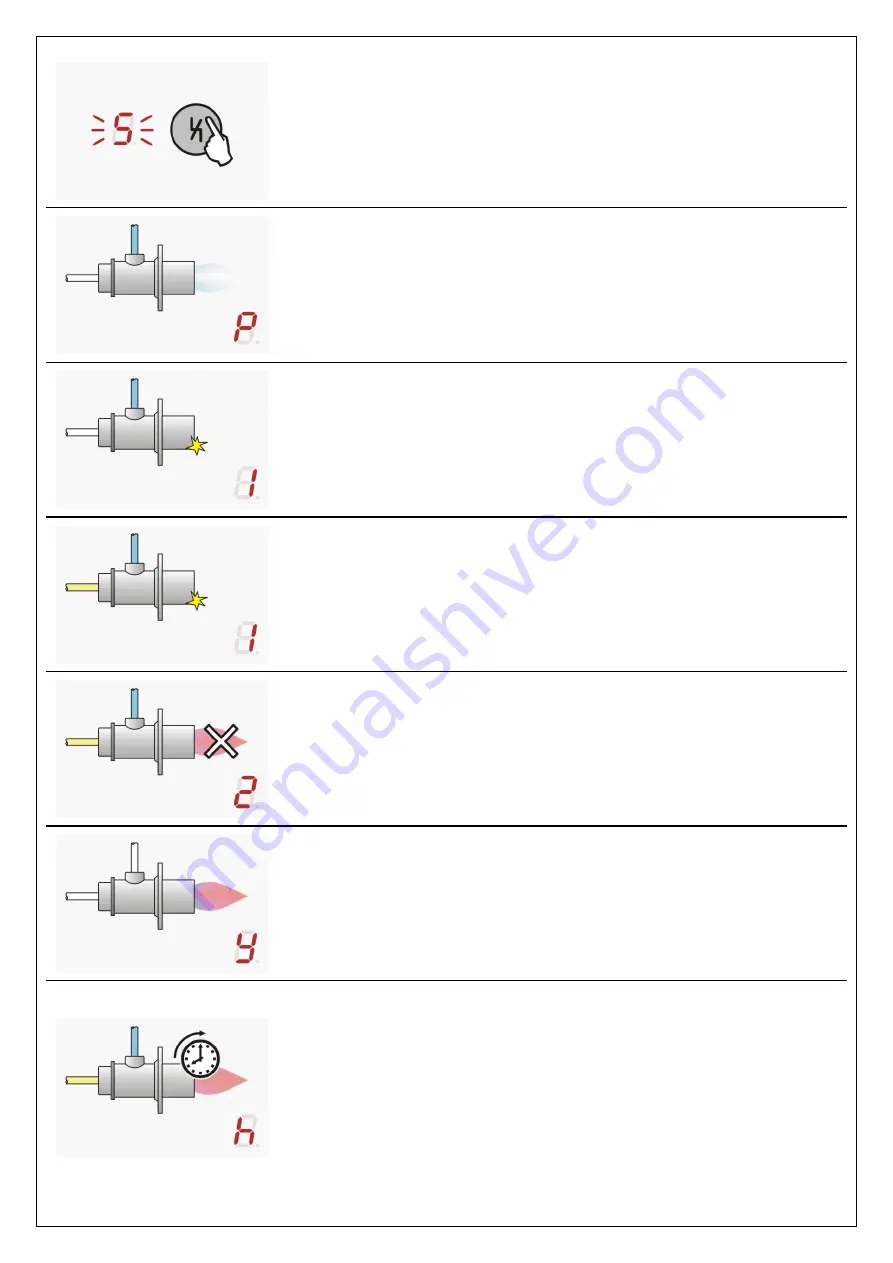

Q101 – START-UP MODE

At power-on, once the self-test has been successfully completed, the unit waits in

STANDBY mode until a reset operation is performed from local push button or

through a fieldbus remote command. Setting AUTOSTART mode, the cycle starts

automatically, unless the units has been turned off while in lockout.

Q305 – PREPURGE TIME

Set prepurge time in forced draught burners according to EN 676 requirements.

Any air valve and/or butterfly valve controlled by external process must be kept

open during the whole prepurge time.

During this time an illegal flame test is carried out.

Q401 – PRE-IGNITION TIME

The ignition transformer is turned on 500 ms before the gas valve to check the

correct operation before to open the gas.

This is a fixed time and cannot be changed.

Q402 – STARTUP SAFETY TIME

Set the correct time following EN 746-2 (or other relevant) requirements:

Natural draught burners

≤ 70 kW → 10”

> 70 kW → 5”

IGNITION POWER ≤ 33% NOMINAL POWER WITH MAXIMUM OF 350 KW

Forced draught burners

≤ 350 kW → 5”

>350kW→3”

IGNITION POWER ≤ 10% NOMINAL POWER WITH MAXIMUM OF 350 KW

Q507 – OPERATING SAFETY TIME

If the flame fails during operation, gas valve is switched off within this safety time

that must be in accordance with relevant application standards (default for EN 298

is 1” and must not exceed 3” including valves closing time for EN 746-2).

F508 – ALLOWED POST-COMBUSTION TIME

The flame signal is allowed for 20” once gas valve has been closed.

Lockout occurs if the flame is detected after the post-combustion time.

Q509 – AUTO SHUT-OFF TIME

An automatic shutoff is performed after the specified time since burner on.

Q510 – AUTO SHUT-OFF MODE

Behavior after an automatic shut-off. In AUTOMATIC mode a complete burner

restart cycle is deployed, performing the test of the whole system, as per Standard

requirements, within 24 hours of continuous operation.

In MANUAL mode the burner waits for reset.