7

Form No. 256827 Rev. 11/08

PVR50 PUMP REPAIR PROCEDURES

DISASSEMBLY PROCEDURE

NOTE: Disassembling pump to change

components, or for any other reason, may

void the warranty. Refer to Policy

Statement and Discounts Summaries.

1. Remove the key (22) in the rotor shaft keyway.

2. Remove the eight cover bolts and slide the cover

back far enough on the shaft to break the seal

between the housing and cover to allow the pump to

drain. A small amount of oil may remain in the pump.

3. Remove the cover. Take care to avoid damage to

the bearing with the end of the shaft when the cover

is removed.

4. The port plate (4) may come out with the cover. Do

not let it drop off the locating pins.

5. Remove the vanes (7) with a long nosed pliers or

tweezers. There are four vanes in each slot, 52

vanes total.

6. Remove the rotorshaft (3) from the pump. Be sure

that the key (22) has been removed from the keyway

so that it will not damage the shaft seals when the

rotorshaft is removed.

7. Turn the pressure adjustment screw (30)

counterclockwise to release the tension on the

governor spring.

8. Remove the pressure ring (6), ring shoe (11),

governor spring (9), retainer (41) and spring (10).

9. If the shaft seals (24) are to be removed they

should be pushed out from the inside of the housing

at this time. Care must be taken not to damage the

bearing bushing (21) in the housing while the shaft

seals are being removed. It is recommended that the

shaft seals be replaced whenever the pump is

disassembled for maintenance. The seals cannot be

reused once they have been removed.

10. The bearing bushing (21) in the pumps are

assembled with a press fit. If they are to be removed

at this time, the bearing in the housing should be

pressed out from the front. The cover bearing should

be pulled out using an expanding type puller. The

bearings should not be reused once they have been

removed.

11. It is unlikely that further disassembly will be

necessary in order to perform routine maintenance on

the pump.

REASSEMBLY PROCEDURE

1. Clean and inspect parts to determine which parts

are worn enough to require replacement.

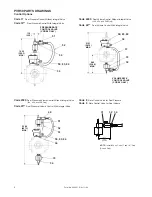

2. Assemble the new bearings (21) in the housing

and cover. The bearing OD's should be lubricated

before they are pressed in the bores. Care must be

taken to orient the "split" and the "oil groove" in the

bearing as shown in the illustration below.

3. After the bearings are in place, check to see that

the rotor shaft (3) will fit into the bearings and provide

a smooth turning fit. If the shaft turns hard, the

bearings should be removed and the bores checked

closely for nicks or burrs before pressing in the new

bearings.

4. Check all of the replacement parts for nicks or

burrs and then lubricate them with clean oil before

reassembly.

5. Worn port (4) and thrust plates (5) should not be

reground to clean up the wear surface. If the plates

are ground, the assembly clearance will become

excessive and the seal rings in the thrust plate may

rupture. Replace worn port and thrust plates if

necessary.

6. Assemble the port plate (4) on the locating pins

(23) in the body housing. If the bores are not

concentric, the port plate must be rotated 180° on the

locating pins.

7. Assemble the springs (9 and 10) and ring shoe

(11), pressure ring (6) and rotorshaft (3).

8. To assure proper vane assembly, place the vanes

(7), four per slot, with the beveled edges facing each

other and against the pressure ring.

Spring Housing

CL

Oil Groove Position

Align Split Line

With Thrust Screw

Item #21

Bushing Bearing Orientation

45°

Pressure Ring

Rotor Shaft

Vanes

Item #7

Typical Vane Installation