P M 13 7 9

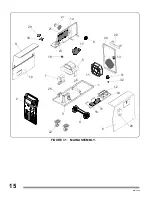

6

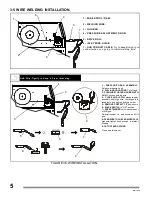

Obtain gas cylinder and chain to running gear, wall, or other

stationary support so cylinder can not fall and break off valve.

1.- CAP.

2.- CYLINDER VALVE.

Remove cap, stand to side of valve, and open valve slightly.

Gas flow blows dust and dirt from valve. Close valve.

3.- CYLINDER.

4.- REGULATOR /FLOWMETER.

5.- GAS HOSE CONNECTION.

6.- FLOW ADJUST.

Typical flow rate is 20 cfh ( Cubic Feet per Hour).

FIGURE 3-6 SHIELDED GAS CONNECTIONS.

1

2

3

6

5

4

3-6 SHIELDED GAS CONNECTIONS.

WARNING

SEE SAFETY SIGNAL AT THE BEGINING THIS M ANUAL

28.5, 15.8mm (1-1/8",5/8")

Tools Needed

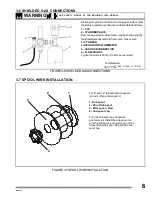

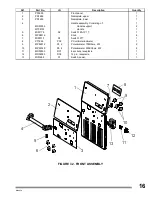

3-7 SPOOL WIRE INSTALLATION.

For 8" and 12" (standard) wire spools

turn unit off and disconnect it.

1.- Hub spool.

2.- Pin of Hub spool.

3.- Wire spool / Reel.

4.- Hud spool cap.

Turn the hub spool cap clockwise

and remove it. Install the wire spool, be

sure the hub spool´s pin enters one of the

holes of the wire spool. Reinstall the hub

spool cap.

1

2

3

4

FIGURE 3-7 SPOOL WIRE INSTALLATION.