CAUTION

8. INSTALL THE CONNECTING PIPE

Check whether the height drop between the indoor unit

and outdoor unit, the length of refrigerant pipe, and the

number of the bends meet the following requirements:

All field piping must be provided by a licensed

refrigeration technician and must comply with the

relevant local and national codes.

Do not let air, dust, or other impurities fall in the pipe

system during the time of installation.

The connecting pipe should not be installed until the

indoor and outdoor units have been fixed already.

Keep the connecting pipe dry, and do not let moisture in

during installation.

The Procedure of Connecting Pipes

8.1

Table 8-1

CAUTION

How to connect the pipes

Drill a hole in the wall (suitable just for the size of the wall

conduit), then set on the fittings such as the wall conduit and

its cover.

Bind the connecting pipe and the cables together tightly with

binding tapes.

Pass the bound connecting pipe through the wall conduct

from outside. Be careful of the pipe allocation to do on

damage to the tubing.

Connect the pipes. Refer to "How to Connect the pipes" for

details.

Expel the air with a vacuum pump. Refer to "How to expel the

air with a vacuum pump" for details.

open the stop values of the outdoor unit to make the

refrigerant pipe connecting the indoor unit with the outdoor

unit in fluent flow.

Check the leakage. Check all the joints with the leak detector

or soap water.

Cover the joints of the connecting pipe with the soundproof /

insulating sheath (fittings), and bind it well with the tapes to

prevent leakage.

Execute heat insulation work completely on both sides of

the gas piping and the liquid piping. Otherwise, this can

sometimes result in water leakage.

1

2

3

5

6

7

4

Be sure to with insulating materials cover all the exposed

parts of the flare pipe joints and refrigerant pipe on the

liquid-side and the gas-side. Ensure that there is no gap

between them.

Incomplete insulation may cause water condensation.

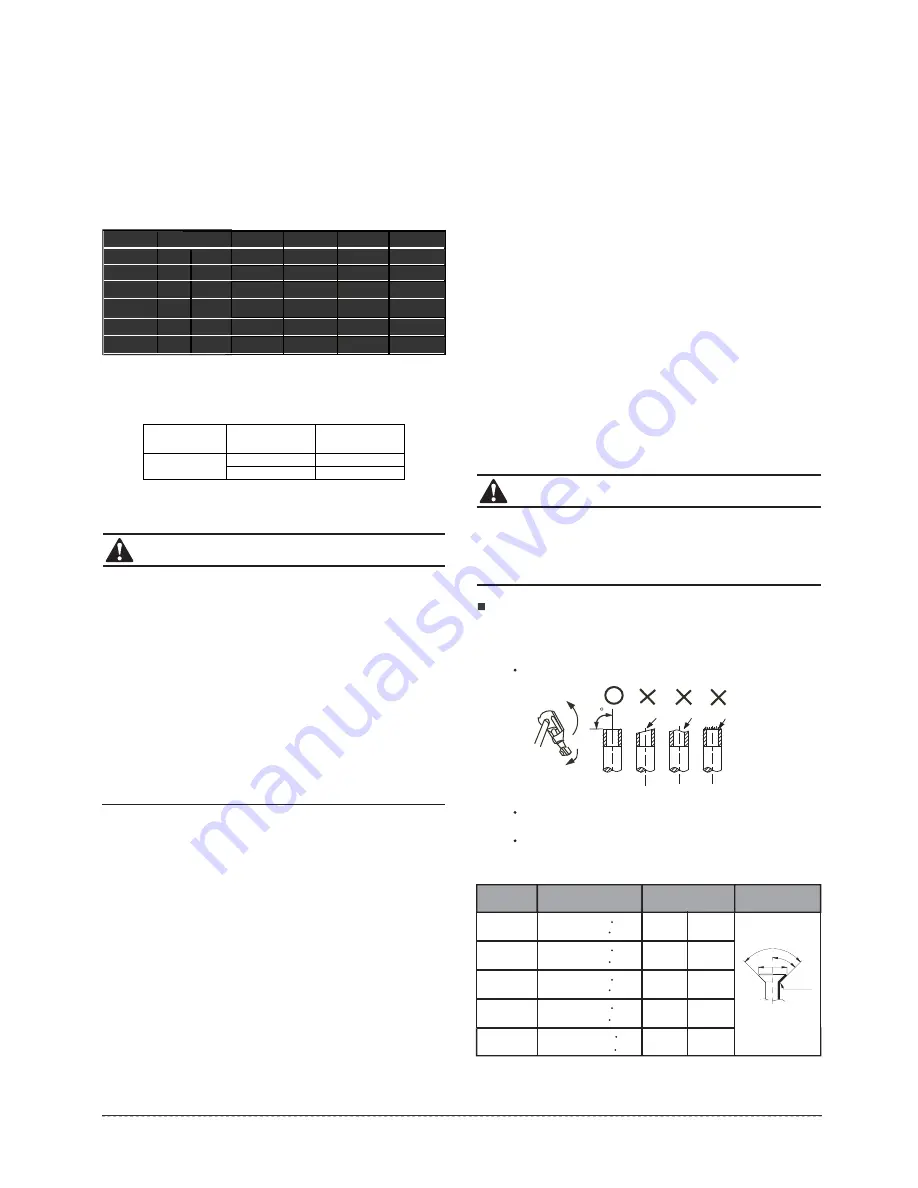

Flaring

1

Cut a pipe with a pipe cutter.

(refer to Fig.8-1)

Ta b le 8-2

Ø6.4

8.3 8.3

Ø9.5

12.0 12.4

Ø12.7

15.4 15.8

Ø15.9

Ø19.1

18.6 19.0

22.9 23.3

R0.4~0.8

45

°±

2

90

°

±

4

A

Insert a flare nut into a pipe and flare the pipe.

Refer to Table 8-2 for the dimension of flare nut spaces.

Fig.8-1

Pipe gauge

Tightening torque

Flare dimensin A

Flare shape

90

Lean crude burr

11

installation manual

min max

(mm)

14.2

~

17.2 N m

(144

~

176 kgf cm)

32.7

~

39.9 N m

(333

~

407 kgf cm)

49.5

~

60.3 N m

(504

~

616 kgf cm)

61.8

~

75.4 N m

(630

~

770 kgf cm)

97.2

~

118.6 N m

(990

~

1210 kgf cm)

Csapacit

Btu/h

12k

18k

24k

36k

48k

Ptipe size

GAS

LIQUID

12'

12'

(Ø12.7)

12'

(Ø12.7)

58''

(Ø16.0)

58''

(Ø16.0)

58''

(Ø16.0)

38''

(Ø9.52)

38''

(Ø9.52)

38''

(Ø9.52)

14''

(Ø6.35)

(Ø6.35)

14''

Ptipe size

Standard

length

Max.

Elevation

Standard

length

Max.

Lenth

Additional

refrigerant

(ft)

(ft)

(ft)

(oz/ft)

25

25

25

25

25

98

98

82

66

33

213

164

98

82

213

213

0.320

0.160

0.160

0.320

0.320

Some systems require additional charging depending on pipe lengths. The standard pipe length

varies according to local regulations. In North America, the standard pipe length is 7.5m (25ft).

The additional refrigerant to be charged can be calculated using the following formula:

Diameter of liquid pipe

(mm)

Φ6.35mm

(

1/4 in

)

Φ9.52 (3/8 in)

Formula

V=15g/m×(L-7.5)

V=30g/m×(L-7.5)

V=0.16oz/ft x (L-25ft)

V=0.32oz/ft x (L-25ft)