104463-01E

For more information, visit www.desatech.com

For more information, visit www.desatech.com

14

CLEANING AND

MAINTENANCE

WARNING: Turn off heater and let cool before

cleaning.

CAUTION: You must keep control areas, burner, and

circulating air passageways of heater clean. Inspect

these areas of heater before each use. Have heater

inspected yearly by a qualified service person. Heater

may need more frequent cleaning due to excessive lint

from carpeting, pet hair, bedding material, etc.

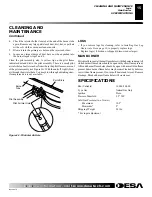

CLEANING BURNER INJECTOR HOLDER

AND PILOT AIR INLET HOLE

The primary air inlet holes allow the proper amount of air to mix with

the gas. This provides a clean burning flame. Keep these holes clear of

dust, dirt, lint, and pet hair. Clean these air inlet holes prior to each

heating season. Blocked air holes will create soot. We recommend that

you clean the unit every three months during operation and have heater

inspected yearly by a qualified service person.

We also recommend that you keep the burner tube and pilot

assembly clean and free of dust and dirt. To clean these parts we

recommend using compressed air no greater than 30 PSI. Your local

computer store, hardware store, or home center may carry com-

pressed air in a can. You can use a vacuum cleaner in the blow

position. If using compressed air in a can, please follow the direc-

tions on the can. If you don't follow directions on the can, you could

damage the pilot assembly.

Note:

Removing the rear panel and top

grates of your stove will make cleaning easier.

1.

Shut off the unit, including the pilot. Allow the unit to cool for

at least thirty minutes.

2.

Inspect burner, pilot, and primary air inlet holes on injector

holder for dust and dirt (see Figure 25).

3.

Blow air through the ports/slots and holes in the burner.

Figure 25 - Injector Holder On Outlet Burner Tube

1.

Follow steps 1 through 5 under Lighting Instructions, page 13.

2.

Depress control knob and light pilot with match.

3.

Keep control knob pressed in for 30 seconds after lighting

pilot. After 30 seconds, release control knob. Now follow

step 8, Lighting Instructions, page 13.

MANUAL LIGHTING

PROCEDURE

OPERATING HEATER

Continued

INSPECTING BURNERS

Check pilot flame pattern and burner flame patterns often.

PILOT FLAME PATTERN

Figure 23 shows a correct pilot flame pattern. Figure 24 shows an

incorrect pilot flame pattern. The incorrect pilot flame is not touching

the thermocouple. This will cause the thermocouple to cool. When the

thermocouple cools, the heater will shut down.

If pilot flame pattern is incorrect, as shown in Figure 24

• turn heater off (see To Turn Off Gas to Appliance, page 13)

• see Troubleshooting, pages 16 through 18

Note:

The pilot flame on natural gas units will have a slight curve,

but flame should be blue and have no yellow or orange color.

Figure 23 - Correct Pilot Flame

Pattern

Figure 24 - Incorrect Pilot

Flame Pattern

Thermocouple

Pilot Burner

Burner Tube

Injector Holder

(May Be Brass

or Aluminum

Depending on

Model)

Primary Air Inlet Holes

(Shape of Holes May

Vary by Model)

Thermocouple

Pilot Burner

OPERATING HEATER

Manual Lighting Procedure

INSPECTING BURNERS

CLEANING AND MAINTENANCE

Cleaning Burner Injector Holder and Pilot Air Inlet Hole