4

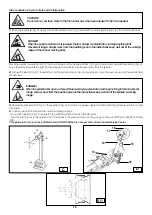

DANGER!!

Do not inflate the tire with the tire assembly on the spindle. Tire inflation is potentially hazardous and should

only be done by removing the tire assembly from the spindle and placing it inside a safety cage.

14

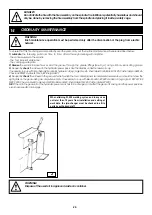

ORDINARY MAINTENANCE

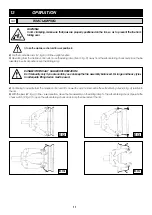

WARNING!

Each maintenance operation must be performed only after the disconnetion of the plug from electric

network.

To ensure that this tire changer works perfectly over the years, carry out the routine maintenance schedule described below:

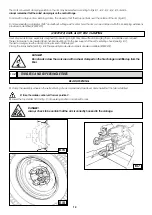

1) Lubricate

the following parts from time to time, after a thorough cleaning with naphtha:

- the various swivels on the spindle

- the tool bracket slide runner

- the carriage guide plate.

2) Grease

the spindle bracket swivel. Add the grease through the grease fittings (See Fig. J) using ordinary lubricating grease.

3)

Frequently

check

the oil level in the hydraulic power pack. Use the dipstick under the reservoir cap.

If necessary top up with Esso Nuto H46 or similar hydraulic oil (eg, Agip Oso 46, Shell Tellus Oil 46, Mobil DTE 25, Castrol Hyspin AWS 46,

Chevron RPM EP Hydraulic Oil 46, BP Energol HLP).

4)

Frequently

check

the oil level in the gear unit which, when the tool carrier bracket is completely lowered down, should not show the

sight glass on the gear casing as completely empty. If necessary top up with Esso Spartan EP 320 or similar oil (eg, Agip F1 REP 237, BP

GRX P 320, Chevron Gear Compound 320, Mobil Gear 632, Shell Omala Oil 320, Castrol Alpha SP 320).

NB: I

f the oil in the gear unit or the hydraulic power pack has to be changed, note that the gear unit casing and the power pack res-

ervoir have specific drain plugs.

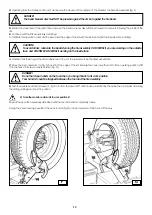

WARNING!

Dispose of the used oil in approved waste oil container.

J

When attaining .000 working cycles, and in any case

not later than 10 years from installation and setting at

work date, the tyre-changer must be checked in all its

parts by authorized staff.