23

P/N 192047138 Rev AA November 2017

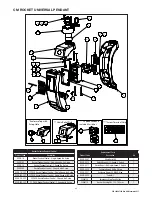

DISASSEMBLY-ASSEMBLY

When disassembling and assembling the Shopstar Hoist, refer to

the exploded view and the parts list on pages 15 through 18.

These show the proper relationship of the parts, the names of the

parts and the required quantities of the parts. In addition, please

observe the following:

1. Needle bearings are pressed into the gear housing, main

frame, liftwheel and lower sheave wheel. Unless they are to

be replaced, do not attempt to remove these bearings.

2. A liftwheel seal is pressed into the main frame and a seal

is pressed into the end of the liftwheel shaft. Be careful

that these seals are not cut or damaged during disassembly

and reassembly.

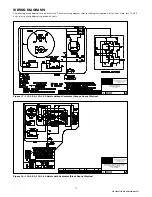

Figure 24 - Main Frame

3. Refer to page 13 for disassembly, inspection, reassembly

and adjustment of the brake.

4. Do not attempt to disassemble the Protector™ - refer to

page 13.

5. Refer to page 14 for lubrication instructions.

6. See next section for load chain removal and installation.

7. Tighten the various screws as follows:

Table 6 - Torque Settings

Part Name

Seating

lb·in

Torque (N·m)

Pin Retainer Plate Screw

25

2.8

Motor Cover Screw

25

2.8

Gear Housing Screw

25

2.8

Brake End Cover Screw

25

2.8

Dead End Plate Screw

125

14.1

Hook Retainer Screw

10

1.1

Hook Block Screw, Double-reeved, 500,

600 and 1,000 lb (226, 272 and 453 kg)

125

14.1

Hook Block Screw, Single-reeved, 250,

300 and 500 lb (113, 136 and 226 kg)

50

5.6

Power Cord Ground Screw

20

2.2

8. When removing the stator , first remove the brake end cover.

Disconnect stator leads from the wiring or contactor. At the

other end, remove the motor end cover. On single phase

units, use an insulated screw driver to short between the bare

terminals of the capacitor to discharge it. A spark may be

produced. Disconnect wiring to the capacitor and then remove

the capacitor. Remove the cut-out device and disconnect the

wires from it. Remove the rotor assembly and thrust washer.

Then slide the stator out of the main frame.

Pin Retainer Plate

Wire

Slot

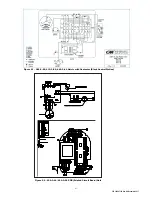

Figure 25 - Stator Installation

9. To install the stator, (Refer to Figure 24) and make sure that the

pin retainer plate has been assembled to the main frame. On

single phase units slide jumpers “2” and “CAP” through the

wire slot in the main frame. Route these wires around the rotor

bearing boss in the main frame as shown in Figure 25. Attach

the brown and blue stator leads and “2” jumper to cut-out

device (refer to wiring diagram). Slide the cut-out device into

the cavity as shown. Push the cut-out device down until it sets

on the main frame. Place the capacitor on top of the cut-out

device and attach “CAP” jumper and the yellow stator lead to

it. Re-route jumpers “2” and “CAP”, if necessary to make sure

they clear the rotor bearing boss as shown in Figure 25. On all

units slide stator leads through wire slot. Align the slots in the

stator shell with the threaded holes in the main frame, as shown

in Figure 24. With the leads down, slide the stator into the main

frame. Slide the rotor, large bearing first, into stator. Place

the rotor thrust washer on top of the exposed rotor bearing

and then assemble the motor end cover to the main frame.

Using wiring diagram, complete the wiring at the brake

end of the unit.

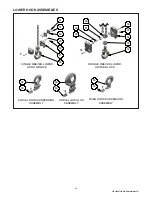

10. Properly install the upper hook as shown in Figure 27, then

slide the hook retainer into the cavity on top of the hoist and

secure it using hook retainer screw. Tighten screw to a seating

torque of 10 in. lbs. (1.1 NM).

LOAD CHAIN REMOVAL/INSTALLATION

1. If unit has a chain container, remove it from the chain guide.

2. Remove the chain stop. Depress DOWN button and run chain

out of hoist.

Figure 26: Chaining Hoist