M01W

45H

6-0

6

WSAT-SC

75C-180F

- G E N E R AL -

5

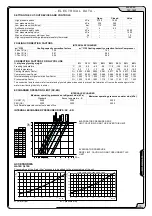

TECHNICAL CHARACTERISTICS OF STANDARD UNITS

COMPRESSOR

Scroll compressor complete with: overload thermal protection, high refrigerant discharge temperature, rubber

antivibration mounts, oil charge, acoustic and weather proof cabinet. A oil heater is automatically switched on at the

compressor shut-down to prevent oil dilution by the refrigerant.

STRUCTURE

hot-galvanized and painted plate structure with pre-painted aluminium external panelling to ensure maximum

weatherability. The uniform distribution of the weight of the unit is guaranteed by the base structure, made up of

galvanized and painted plate section bars, and featuring holes to simplify the lifting and earthing of the unit.

AIR EXCHANGER

heat exchange coil with aluminium fins and copper tubes in staggered rows. The coils are complete with integral

subcooling circuit which assures the correct refrigerant feeding of the expansion valve. Available in different options as

per optional list.

WATER EXCHANGER

direct expansion heat exchanger, with 316 stainless steel braze-welded plates and large exchange surface, complete

with external anti-condensate heat insulation. Two independent alternating water / freon refrigerant circuits, with cross

flow to optimize heat exchange; complete with safety differential pressure switch on the water side and antifreeze heater

to protect against the risk of freezing.

FAN

Helical fans with sickle-shaped blades with "Winglets" at the end, coupled directly to a three phase electric external rotor

motor with thermal protection incorporated in version IP 54. Housed in aerodynamically shaped nozzles to increase

efficiency and minimize noise levels. They are fitted with protective safety guard grilles.

REFRIGERANT CIRCUIT

The units are made with two independent refrigerant circuits, each with:

- electronic expansion valve (see details further on)

- high pressure switch

- low pressure switch

- high pressure safety valve

- low pressure safety valve

- replaceable anti-acid solid cartridge dehydrator filter

- compressor discharge shut-off valve

- liquid line shut-off valve

- sight glass with moisture indicator

Sizes 75C and 90C are realized only with a single refrigerant circuit.

ELECTRICAL PANEL

the Power Section includes:

- main door lock isolator switch

- isolating transformer for auxiliary circuit power supply

- compressor circuit breaker

- fan overload circuit breakers

- compressor control contactor

- fan control contactors

- phase-cutting fan speed control

the control section includes:

- propor integral water temperature control

- antifreeze protection

- compressor overload protection and timer

- self-diagnosis system with immediate display of the error code

- compressor operating hour display

- remote ON/OFF control

- automatic compressor start rotation control

- relay for remote cumulative fault signal

- input for demand limit (absorbed power limit according to an external signal 0÷10V or 4÷20mA) - except sizes 75C and

90C.

- H2o antifreeze and high refrigerant gas pressure pre-alarm function that reduces cooling capacity to avoid unit shut-

down

- display of the set values, the error codes and the parameter index

- ON/OFF and alarm reset buttons

- UP and DOWN buttons to increase and decrease the values

- interface terminal with graphic display

- possibility of communication with ZONE MASTER system (optional)

Содержание WSAT-SC 100D Series

Страница 2: ......