M01W

45H

6-0

6

WSAT-SC

75C-180F

- S T AR T - U P -

33

VERIFY TENSIONS – ABSORPTIONS

Check that the temperatures of the fluids are included in the WORKING LIMITS.

If the controls of the previous paragraphs are positive, it is possible to restart the unit.

For information on the control panel, refer to the paragraph SETTING.

While the unit is working (ATTENTION ELECTRIC RISK: WORK SAFETLY) check:

•

Power supply tension

•

Phase

unbalance

•

Total absorption of the unit

•

Absorption of the single electric loads

UNIT EQUIPPED WITH SCROLL COMPRESSORS

The GENERAL TECHNICAL DATA table shows the type of compressor on the unit.

The Scroll compressors have only one direction of rotation.

In the event that the direction is reversed, the compressor will not be damaged, but its noisiness will increase and

pumping will be negatively affected. After a few minutes, the compressor will stop because of the activation of the

thermal protection. In this event, cut the power and reverse the 2 phases on the machine power.

Prevent the compressor from working with in reverse rotation: more than 2-3 anomalous starts up can damage it.

Make sure the direction of rotation is correct, measure the condensation and suction pressure. Pressure must clearly

differ: at the start, the suction pressure decreases whilst the condensation pressure increases.

The phase optional monitor, which controls the phase sequence, can be installed later.

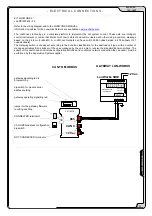

REMOTE INPUT CONFIGURATIONS

Check used remote inputs are activated (ON-OFF etc.) as given in the instructions in the ELECTRIC WIRING chapter.

SETTING THE SET-POINT

Check if it is necessary to modify the set-points shown in the SETTING chapter.

EVAPORATOR WATER-FLOW CHECK

Verify that the difference between the water at the input and at the output of the exchanger is related to the capacity

according to the formula:

refrigerating capacity of the unit (kW) x 860 = Dt (°C) x flow rate (L/h).

The refrigerating capacity is shown in the GENERAL TECHNICAL FEATURE chart of this manual and it refers to specific

water/air conditions or to the tables of COOLING PERFORMANCES on TECHNICAL CHART that refer to different use

conditions.

Verify the loss of charge of the exchanger at the water side:

•

determine the water capacity

•

measure the difference of pressure between the input and output of the exchanger and compare it with the

graph LOSS OF CHARGE OF THE EXCHANGER AT THE WATER SIDE

The pressure measurements will be easier if “M” gauges are installed as shown in the HYDRAULIC CONNECTION

DIAGRAM.

REFRIGERANT CIRCUIT PARAMETER CHECK

Detecting the operational conditions is useful to control the unit along time: the performed records must be kept and be

available during maintenance interventions.

When the unit works in stable conditions and according to the operating limits, take note of the following data:

1. compressor discharge temperature (WARNING – BURN DANGERI)

2. condensing

pressure

3. liquid

temperature

4. dehydrator filter upstream and downstream temperature

5. inlet

pressure

6. inlet

temperature

7. exchanger inlet water temperature

8. exchanger outlet water temperature

9. external air temperature (battery input)

10. air temperature coming out from fans

Содержание WSAT-SC 100D Series

Страница 2: ......