1.3, with a tolerance of ± 5%.

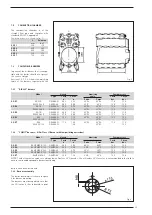

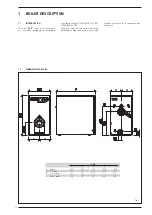

2.1

BOILER ROOM

The boiler room should feature all the

characteristics required by standards

governing liquid fuel heating systems.

2.2

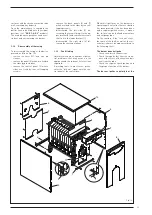

BOILER ROOM DIMENSIONS

Position the boiler body on the founda-

tion bed, which should be at least 10 cm

high. The body should rest on a surface

allowing shifting, possibly by means of

sheet metal.

Leave a clearance between the boiler

and the wall of at least 0.60 m, and

between the top of the casing and the

ceiling of 1 m (0.50 m in the case of boil-

ers with incorporated D.H.W. tank). The

ceiling height of the boiler room should

not be less than 2.5 m.

2.3

CONNECTING UP SYSTEM

When connecting up the water supply

to the boiler, make sure that the speci-

fications given in fig. 1 are observed.

All connecting unions should be easy to

disconnect by means of tightening rings.

A closed expansion tank system must

be used.

2.3.1 Filling the water system

Before connecting the boiler, thorough-

ly flush the system to eliminate scale

which could damage the appliance.

Filling must be done slowly to allow any

air bubbles to be bled off through the air

valves.

In closed-circuit heating systems, the

cold water filling pressure and the pre-

charging pressure of the expansion ves-

sel should be no less than or equal to the

height of the water head of the instal-

lation (e.g. for water head of 5 meters,

the vessel pre-charging pressure and

installation filling pressure should be at

least 0.5 bar).

2.3.2 Characteristics of feedwater

Water supplying the heating circuit must

be treated in accordance with UNI-CTI

8065 standards.

It is absolutely essential to treat water

in the heating system in the following

cases:

– For extensive systems (with high con-

tents of water).

– Frequent addition of water into the sys-

tem.

– Should it be necessary to empty the

system either partially or totally.

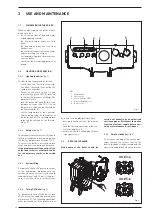

2.4

CONNECTING UP FLUE

The flue is of fundamental importance for

the proper operation of the boiler; if not

installed in compliance with the stand-

ards, starting the boiler will be difficult

and there will be a consequent formation

of soot, condensate and encrustation.

The flue used to expel combustion prod-

ucts into the atmosphere must meet the

following requirements:

– be constructed with waterproof mate-

rials, and resistant to smoke tempera-

ture and condensate;

– be of adequate mechanical resilience

and of low heat conductivity;

– be perfectly sealed to prevent cooling

of the flue itself;

– be as vertical as possible; the terminal

section of the flue must be fitted with

a static exhaust device that ensures

constant and efficient extraction of

products generated by combustion;

– to prevent the wind from creating

pressure zones around the chimney

top greater than the uplift force of

combustion gases, the exhaust out-

let should be at least 0.4 m higher

than structures adjacent to the stack

(including the roof top) within 8 m;

– have a diameter that is not inferior

to that of the boiler union: square or

rectangular-section flues should have

an internal section 10% greater than

that of the boiler union;

– the useful section of the flue must

conform to the following formula:

S resulting section in cm

2

K reduction coefficient for liquid

fuels:

– 0.045 for firewood

– 0.030 for coal

– 0.024 for light oil

– 0.016 for gas

P boiler input in kcal/h

H height of flue in meters, measured

from the flame axis to the top of

the flue reduced by:

– 0.50 m for each change of direc-

tion of the connection union

between boiler and flue;

– 1.00 m for each metre of union

itself.

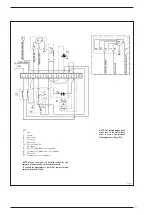

2.5

ELECTRICAL CONNECTION

The boiler is fitted with an electricity

cable, and requires a 1ph - 230V - 50Hz

power supply through the main switch

protected by fuses.

The room thermostat (required for

enhanced room temperature control)

should be installed as shown in fig. 6.

Connect the burner with the cable sup-

plied.

NO TE: Device must be connected to an

efficient earthing system.

CLIMIT de cli nes all responsibility for

injury caused to persons due to failure

to earth the boiler. Always turn off the

power supply before doing any work on

the electrical panel.

26

P

S = K

√

H

2 INSTALLATION

Содержание GG E 3

Страница 1: ...GG E 3 7 Cod 6276052A 07 2019 IT ES ENG FR RUS ...

Страница 5: ...3 1 4 PERDITE DI CARICO CIRCUITO CALDAIA Fig 2 GG E 7 GG E 6 GG E 5 GG E 4 GG E 3 ...

Страница 12: ...10 NOTE ...

Страница 16: ...14 1 4 PERDIDAS DE CARGA Fig 2 Loss of head mbar CAUDAL l h GG E 7 GG E 6 GG E 5 GG E 4 GG E 3 ...

Страница 26: ...24 1 4 LOSS OF HEAD Fig 2 Loss of head mbar Flow l h GG E 7 GG E 6 GG E 5 GG E 4 GG E 3 ...

Страница 36: ...24 1 4 LOSS OF HEAD Fig 2 Loss of head mbar Flow l h GG E 7 GG E 6 GG E 5 GG E 4 GG E 3 ...

Страница 56: ...44 1 4 ПОТЕРИ НАГРУЗКИ Pис 2 ПОТЕРИ НАГРУЗКИ p мБар Расход л час GG E 7 GG E 6 GG E 5 GG E 4 GG E 3 ...

Страница 63: ...51 NOTE ...

Страница 64: ...52 NOTE ...

Страница 65: ......

Страница 66: ...Via Garbo 27 37045 Legnago Vr Tel 39 0442 631111 Fax 39 0442 631292 ...