24

C l i m a t e M a s t e r Wa t e r- S o u rc e H e a t P u m p s

C L I M A T E M A S T E R W A T E R - S O U R C E H E A T P U M P S

Tr a n q u i l i t y

®

3 0 ( T T ) S e r i e s

R e v. : 0 7 / 1 8 / 1 3

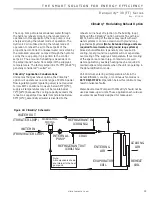

Figure 17: LT1 Limit Setting

CXM PCB

LT1

LT2

JW3-LT1 jumper should

be clipped for low

temperature operation

Electrical - Low Voltage Wiring

Accessory Connections

A terminal paralleling the compressor contactor coil

has been provided on the CXM/DXM control. Terminal

“A” is designed to control accessory devices, such as

water valves. Note: This terminal should be used only

with 24 Volt signals and not line voltage. Terminal “A” is

energized with the compressor contactor. See Figure 18

or the specifi c unit wiring diagram for details.

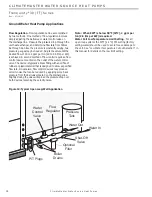

Figure 18: Accessory Wiring

Water Solenoid Valves -

An external solenoid valve(s)

should be used on ground water installations to shut off

fl ow to the unit when the compressor is not operating.

A slow closing valve may be required to help reduce

water hammer. Figure 18 shows typical wiring for a 24VAC

external solenoid valve. Figures 19 and 20 illustrate

typical slow closing water control valve wiring for Taco

500 series (ClimateMaster P/N AVM) and Taco SBV

series valves. Slow closing valves take approximately

60 seconds to open (very little water will fl ow before 45

seconds). Once fully open, an end switch allows the

compressor to be energized. Only relay or triac based

electronic thermostats should be used with slow closing

valves. When wired as shown, the slow closing valve will

operate properly with the following notations:

1. The valve will remain open during a unit lockout.

2. The valve will draw approximately 25-35 VA through

the “Y” signal of the thermostat.

Note: This valve can overheat the anticipator of an

electromechanical thermostat. Therefore, only relay or

triac based thermostats should be used.

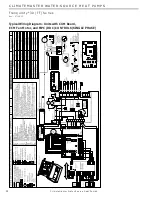

Two-stage Units

Tranquility

®

30 (TT) two-stage units should be designed with

two parallel valves for ground water applications to limit

water use during fi rst stage operation. For example, at 1.5

gpm/ton [2.0 l/m per kW], a TT049 unit requires 6 gpm [23

l/m] for full load (2nd stage) operation, but only 4 gpm [15

l/m] during 1st stage operation. Since the unit will operate

on fi rst stage 80-90% of the time, signifi cant water savings

can be realized by using two parallel solenoid valves with two

fl ow regulators. In the example above, stage one solenoid

would be installed with a 4 gpm [15 l/m] fl ow regulator on

the outlet, while stage two would utilize a 2 gpm [8 l/m] fl ow

regulator. When stage one is operating, the second solenoid

valve will be closed. When stage two is operating, both

valves will be open, allowing full load fl ow rate.

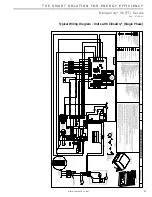

Figure 21 illustrates piping for two-stage solenoid valves.

Review fi gures 21-23 for wiring of stage one valve. Stage

two valve should be wired between terminal “Y2” (ECM

board) and terminal “C.” NOTE: When EWT is below

50°F [10°C], 2 gpm per ton (2.6 l/m per kW) is required.

Low Voltage VA Ratings

Component

VA

Typical Blower Relay

6 - 7

Typical Reversing Valve Solenoid

4 - 6

30A Compressor Contactor

6 - 9

Subtotal

16 - 22

+ CXM board (5 - 9 VA)*

21 - 31

Remaing VA for Accessories

19 - 29

+ DXM board (8 - 12 VA)*

24 - 34

Remaing VA for Accessories

41 - 51

*Standard transformer for CXM board is 50VA.

Optional DXM board and/or DDC controls

include 75VA transformer.