Maintenance

5-6

750-297

Profire E/LNE Series Manual

5.12 — Primary Compressor System

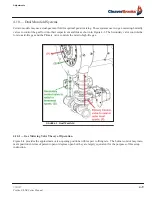

5.12.1 — Primary Compressor

The air compressor itself requires little maintenance, however, its life is dependent upon sufficient clean, cool

lubricating oil. The oil level in the air-oil tank must be checked regularly. Lack of oil will damage the compressor.

Disassembly or field repairs to the air compressor are not recommended. Check the air-oil tank sight glass for proper

oil level. the level should be kept at midpoint up the glass. The compressor rotor must turn freely. All tube connections

must be air tight.

Alignment of the compressor and motor sheaves and proper belt tension are important.

Belt tension is adjusted according to the displacement on the belt with thumb pressure. The displacement should be 3/8

to 1/2 inch.

To adjust, loosen the two bolts on the compressor mounting flange and the three setscrews which hold the compressor

in place.

The mounting flange is slotted at the top, which permits belt tightening. If the slot in the mounting flange is insufficient

for obtaining proper belt tension, the modular base has two extra holes for this purpose.

Move the top bolt to the next hole and adjust. Tighten bolts and setscrews. Replace belt guards. Replace the belt if it

becomes frayed or cracked.

5.12.2 — Air Cleaner

Never operate the compressor without the air cleaner in place. The cleaner should be cleaned at regular intervals. The

correct oil level must be maintained in the air cleaner. Use the same oil used for air compressor lubrication.

5.12.3 — Air-Oil Tank

Check the lube oil level in the air-oil tank. Inspect oil level regularly as loss of oil will damage the compressor. Change

oil every 2,000 hours of operation. The air-oil tank should be drained once a year and thoroughly flushed. Remove the

mist eliminator pads or steel wool (No. 3 coarse grade American steel wool or equivalent) from the upper section of the

tank, wash thoroughly in kerosene and dry. Refill with non-detergent SAE30 oil to a level midway up the sight glass.

For normal environment use SAE30 oil. For a 32º F and below environment use SAE10 oil.

Do not attempt to disassemble the oil metering pump in the field. Any attempt will void the warranty or the exchange policy.

The metering pump is lubricated by fuel oil and must not be operated longer than one minute if it’s not pumping oil. Failure

to comply will result in premature pump failure and void any warranty implied or otherwise.

!

Caution

!

Caution

Содержание Profire E Series

Страница 2: ...E LNE SERIES Installation Operation and Service Manual Manual Number 750 297 Release Date July 2019...

Страница 24: ...Introduction 1 10 750 297 Profire E LNE Series Manual...

Страница 44: ...Operation 3 8 750 297 Profire E LNE Series Manual...

Страница 70: ...Troubleshooting 6 6 750 297 Profire E LNE Series Manual...

Страница 79: ...750 297 Profire E LNE Series Manual 8 5 LNE Series FGR System FIGURE 8 4 Temperature Interlocks...

Страница 82: ...750 297 Profire E LNE Series Manual...